- Messages

- 1,325

- Reaction score

- 1,745

- RC Driving Style

- Racing

Way back when I first started my first nitro drag car setup, I had thought about adding nitrous to it, and was (correctly) talked out of it. While they "sort of" work (and you'll hear a lot of passionate, varied opinions on that), the implementation really isn't useful, IMO. Back in the day, Nitrous Express came out with an RC nitrous system. It was very similar in design to the 1:1 system they sold. It used a mechanical switch to release the nitrous into the carb when the throttle was open past a certain point. Then RB Innovations came out with one that was nearly identical and just as poorly implemented if not worse. This design was really good for one thing - ruining your engine. Now I have seen a number of videos, that do show it "working" and creating a lot of power, the tradeoff isn't worth it. Better to use higher nitro content fuel, or a bigger engine.

But what about a system that is controlled by a button on the remote, aka, a "Scramble button"? Something that was toggled on/off for a split second or so at the end of a run. Same lean-out conditions would be there of course, so what about a "wet" system? You know, one that actually mixes fuel with the nitrous using a small fuel rail that pushes fuel into the mix? I was thinking about all of this not really for nitro engines, but for 4-stroke mini v-8's that are coming out, but I did wonder if it could also be useful for a nitro drag car.

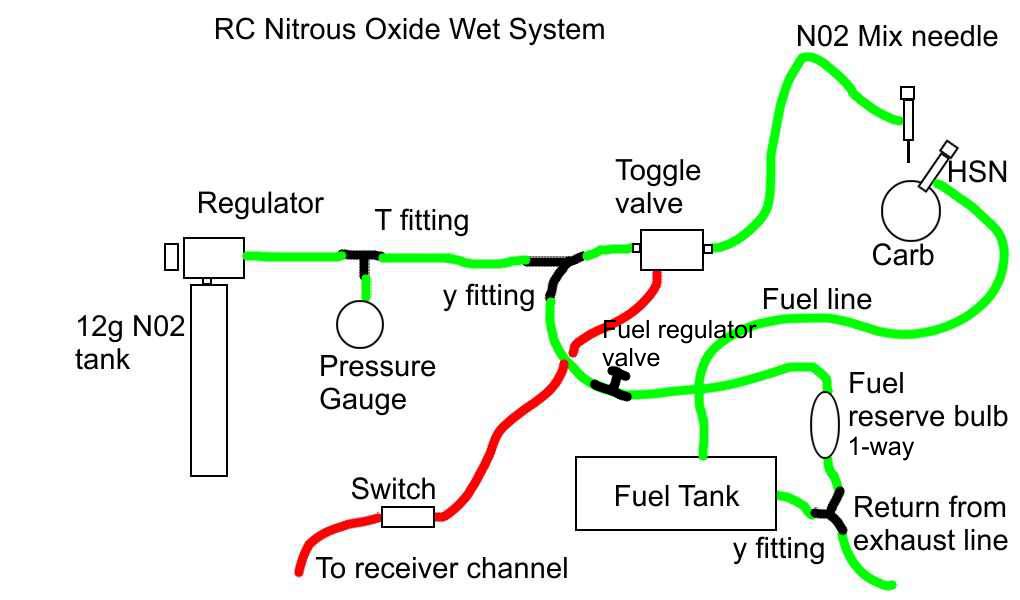

So I got to researching needed parts, and designing after doing a good bit of research of the 1:1 designs:

When armed, there is fuel in the bulb and line running to the Y fitting on the nitrous line, and there is pressurized nitrous in the line running from the tank to the toggle valve. The fuel is held in due to the bulb being a 1-way valve itself, and not being forced into the exhaust line. When activated, the nitrous flows past the toggle valve along with fuel that is in the bulb that is being sucked as well as pushed by the exhaust pressure. The amount of fuel is regulated with a valve. At the end of the line going into the carb (air filter hose) is a needle (a repurposed HSN is ideal fit) to get a spray and regulate the final amount. This may cause a (very) brief moment where gas tank pressure is not 100%, but quickly reverts when the button is released.

Essentially this is used as a scramble button - you hit it for a half second or so and release to get a little extra on the top end. The amount of pressure and N02 being injected should not be a large amount, as that is likely to cause blow-by due to the design of nitro engines. We aren't looking to double the power here - it's a shot of extra, nothing more.

So, I got to building. I already had a bunch of the fittings and line, as well as clips for the connections that potentially could pop off under pressure.

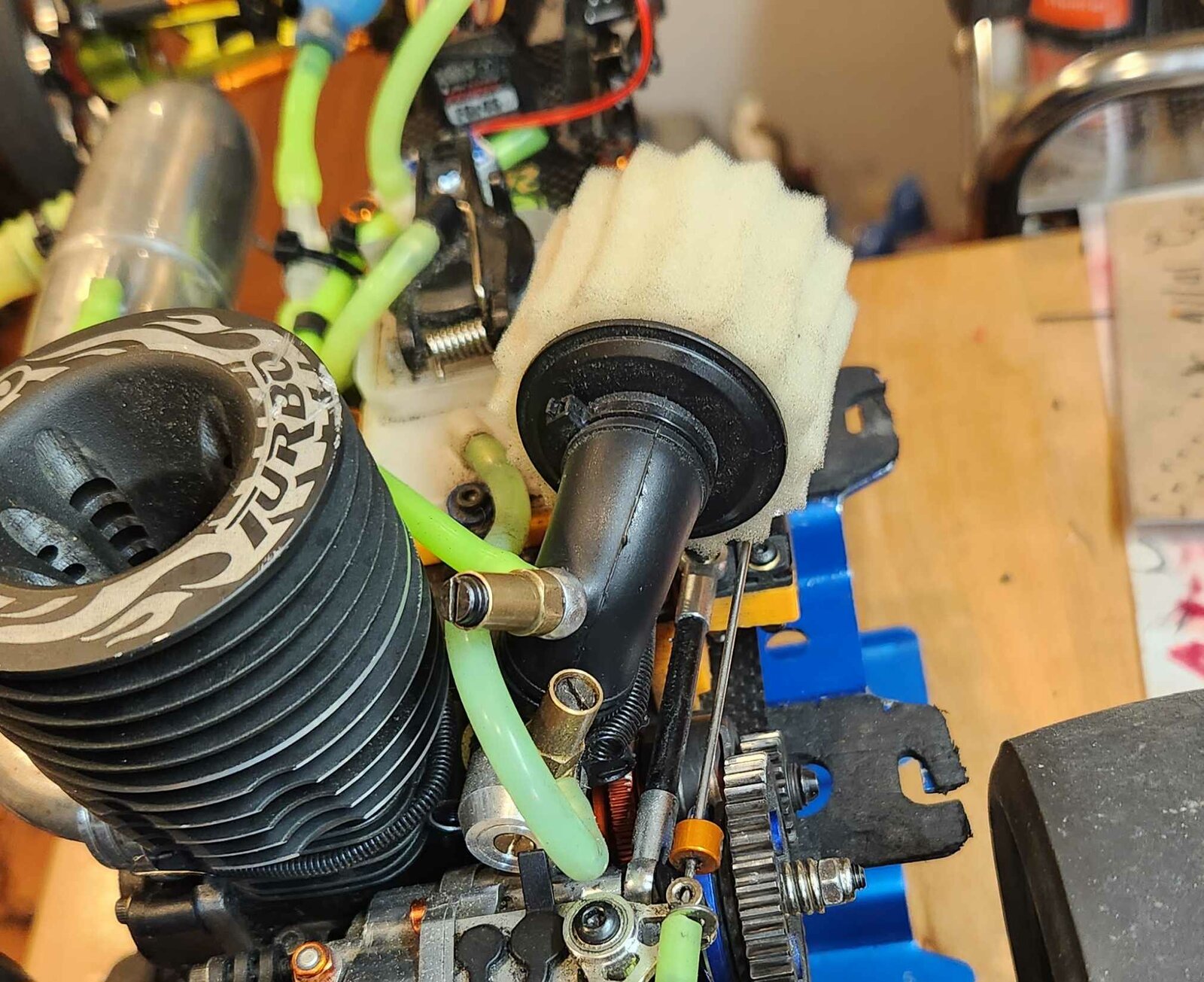

I had nearly everything within a day ordered, and it quickly came together. The HSN was a perfect solution for the nitrous/fuel mixture, and threaded into filter hose securely, at a 90 degree angle to the air flow.

After I had it all together, I made sure there were no air leaks, and I tested the valve action from the radio. Then I ran the car with the system unfilled, and unarmed to make sure the car didn't act funky in any way. It ran just as before. Hooray!

The nitrous bottle is a refillable type as they don't make threaded minis of N02 for some reason. So I'm waiting on the adaptor to allow me to fill it from a nitrous bottle (which I have one of ). Once I have that in hand, I'll be able to see how the system is when the nitrous pressure is released into the line, and hopefully there isn't too much expansion of the lines (or lines popping off). I do have a remedy for the line expansion handy, if necessary, though.

The way to operate this would be a few steps:

1. Disconnect fuel bulb from exhaust line.

2. Close fuel regulator valve, then prime it with fuel. Reconnect.

3. Open fuel regulator valve to desired position. (Here I think I will change to a better valve at some point that has measurements).

4. Open nitrous regulator valve and bring pressure up to desired level. No clue yet what a good level will be, but that'll be the fun part I think.

Questions I still have:

1. How solid is the bulb's 1-way valve? Will nitrous pressure overwhelm it? (If so, maybe a better valve will be required).

2. Will the exhaust pressure + suction of passing N02 be enough to pull enough fuel for a good mix? I think so.

But what about a system that is controlled by a button on the remote, aka, a "Scramble button"? Something that was toggled on/off for a split second or so at the end of a run. Same lean-out conditions would be there of course, so what about a "wet" system? You know, one that actually mixes fuel with the nitrous using a small fuel rail that pushes fuel into the mix? I was thinking about all of this not really for nitro engines, but for 4-stroke mini v-8's that are coming out, but I did wonder if it could also be useful for a nitro drag car.

So I got to researching needed parts, and designing after doing a good bit of research of the 1:1 designs:

When armed, there is fuel in the bulb and line running to the Y fitting on the nitrous line, and there is pressurized nitrous in the line running from the tank to the toggle valve. The fuel is held in due to the bulb being a 1-way valve itself, and not being forced into the exhaust line. When activated, the nitrous flows past the toggle valve along with fuel that is in the bulb that is being sucked as well as pushed by the exhaust pressure. The amount of fuel is regulated with a valve. At the end of the line going into the carb (air filter hose) is a needle (a repurposed HSN is ideal fit) to get a spray and regulate the final amount. This may cause a (very) brief moment where gas tank pressure is not 100%, but quickly reverts when the button is released.

Essentially this is used as a scramble button - you hit it for a half second or so and release to get a little extra on the top end. The amount of pressure and N02 being injected should not be a large amount, as that is likely to cause blow-by due to the design of nitro engines. We aren't looking to double the power here - it's a shot of extra, nothing more.

So, I got to building. I already had a bunch of the fittings and line, as well as clips for the connections that potentially could pop off under pressure.

I had nearly everything within a day ordered, and it quickly came together. The HSN was a perfect solution for the nitrous/fuel mixture, and threaded into filter hose securely, at a 90 degree angle to the air flow.

After I had it all together, I made sure there were no air leaks, and I tested the valve action from the radio. Then I ran the car with the system unfilled, and unarmed to make sure the car didn't act funky in any way. It ran just as before. Hooray!

The nitrous bottle is a refillable type as they don't make threaded minis of N02 for some reason. So I'm waiting on the adaptor to allow me to fill it from a nitrous bottle (which I have one of ). Once I have that in hand, I'll be able to see how the system is when the nitrous pressure is released into the line, and hopefully there isn't too much expansion of the lines (or lines popping off). I do have a remedy for the line expansion handy, if necessary, though.

The way to operate this would be a few steps:

1. Disconnect fuel bulb from exhaust line.

2. Close fuel regulator valve, then prime it with fuel. Reconnect.

3. Open fuel regulator valve to desired position. (Here I think I will change to a better valve at some point that has measurements).

4. Open nitrous regulator valve and bring pressure up to desired level. No clue yet what a good level will be, but that'll be the fun part I think.

Questions I still have:

1. How solid is the bulb's 1-way valve? Will nitrous pressure overwhelm it? (If so, maybe a better valve will be required).

2. Will the exhaust pressure + suction of passing N02 be enough to pull enough fuel for a good mix? I think so.

Last edited: