Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

links, including eBay, Amazon, and others.

More options

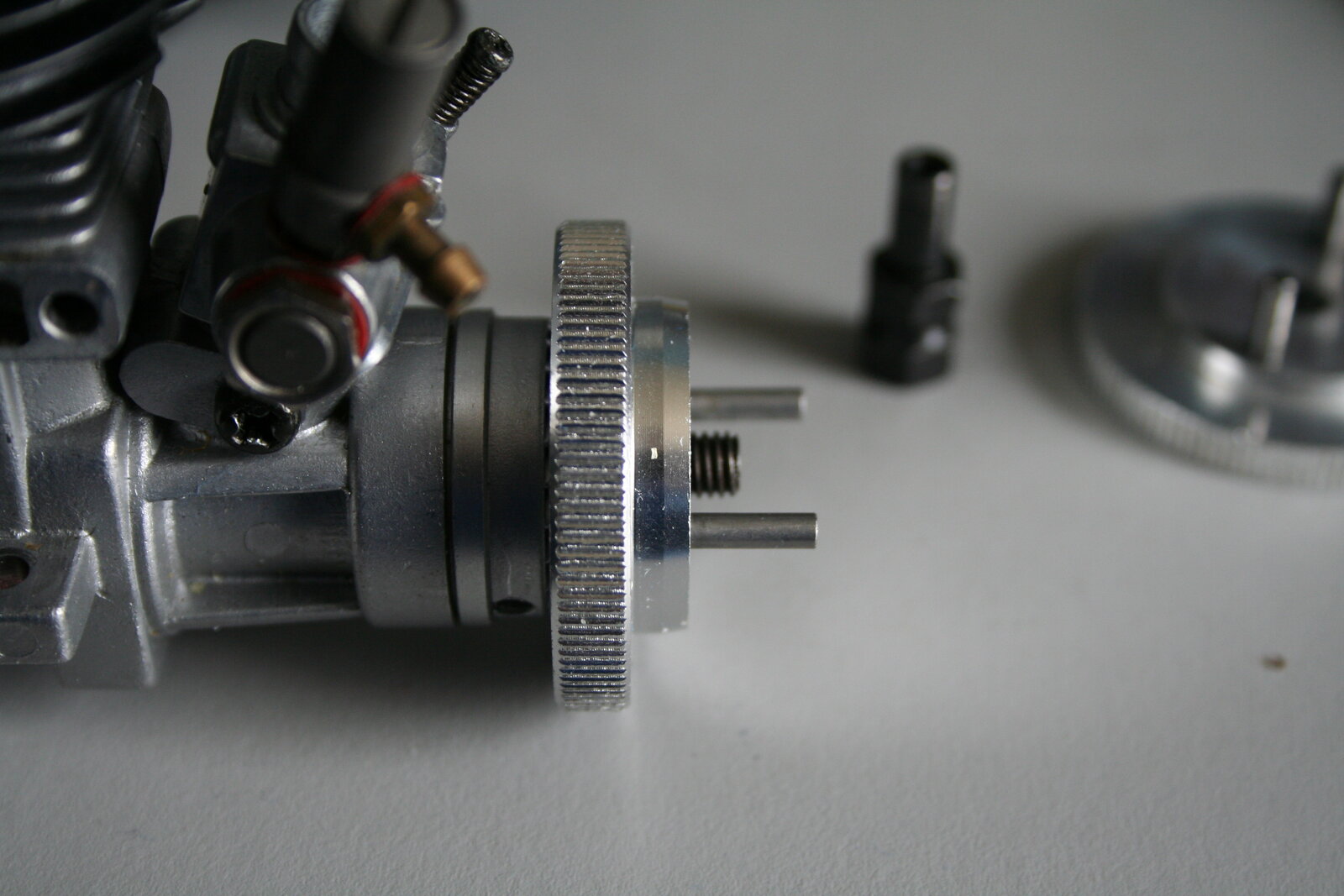

Who Replied?I went to try to install the engine only to find this out. And man, am I fuming.

View attachment 180795

Ah bummer, that's a challenge with matching engine compatibility. The VX-18 has a threaded shaft, while your vehicle was made for an "SG/OS shaft," where the flywheel sits directly against the engine, without that 6.5mm spacer.

I think you'd be best off getting the cheapest compatible engine you can, like an FC-18 for example.

Chubaka

RCTalk VIP

Supporter

Excellence Award

- Messages

- 6,070

- Reaction score

- 10,609

- Location

- Jurassic Park

- RC Driving Style

- Bashing

- Crawling

- Scale Builder

Shorter crank or modify the motor mount. How is spacing behind the motor?

That spacer is also the drive washer, it pinches the flywheel as if it's driving a propeller. They would need a brass cone and the press-fit style of flywheel to replace it, as well as cutting short the end of the crank.Can you pull that aluminum spacer off and mount the flywheel and collet closer?

Or what's behind the clutch bell, can that be moved closer in?

It can be done, people used to do that to adapt threaded-shaft engines which is why SG-shaft was innovated in the first place.

Grizz03

RCTalk Qualifier

- Messages

- 165

- Reaction score

- 117

- RC Driving Style

- Bashing

That spacer is also the drive washer, it pinches the flywheel as if it's driving a propeller. They would need a brass cone and the press-fit style of flywheel to replace it, as well as cutting short the end of the crank.

It can be done, people used to do that to adapt threaded-shaft engines which is why SG-shaft was innovated in the first place.

Like the brass collet and flywheel on a traxxas for instance. I did the same on an old Aquacraft engine.

I was only thinking if the original engine didn't require that spacer shouldn't it already be a collet and taper fit flywheel?

Last edited:

Grizz03

RCTalk Qualifier

- Messages

- 165

- Reaction score

- 117

- RC Driving Style

- Bashing

I thought that's how it would work. Glad you got it sorted out and installed.Alright, so it looks like some parts of the old motor are interchangeable. Once I took off the extension that attaches to the motor shaft and echanged it with the old one, the engine fit like a glove.

infernoprime

RCTalk Member

- Messages

- 37

- Reaction score

- 8

- Thread starter

- #9

Well, I might have run into problems. I will need a few days to sort things out.I thought that's how it would work. Glad you got it sorted out and installed.

infernoprime

RCTalk Member

- Messages

- 37

- Reaction score

- 8

- Thread starter

- #10

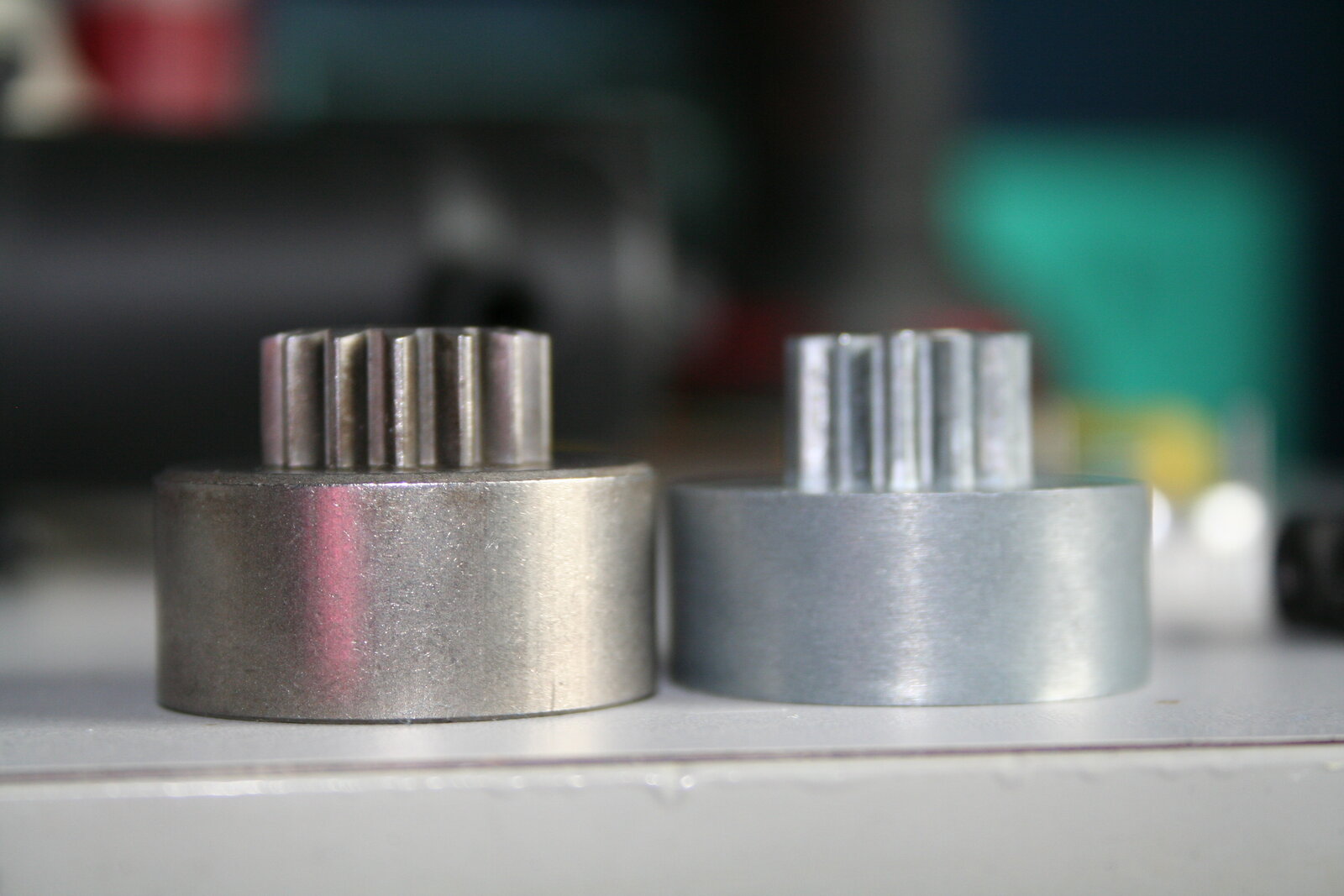

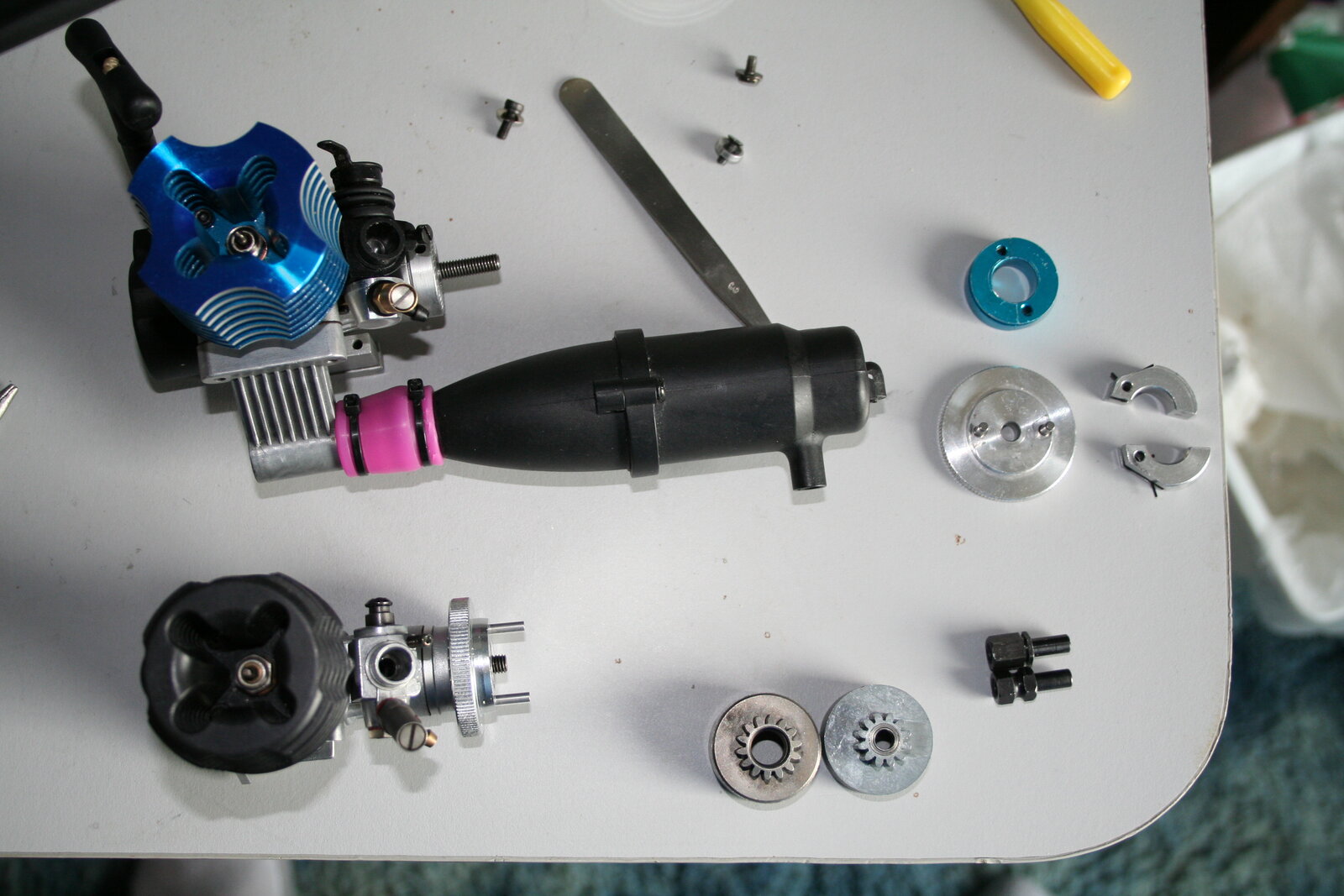

For a little more clarity, I took some more pictures to explain things more.

Here are the shaft sizes.

Engine shaft size difference

Original engine shaft size

Other parts pictures

Has anyone ever had to grind down an engine shaft to fit before?

Here are the shaft sizes.

Engine shaft size difference

Original engine shaft size

Other parts pictures

Has anyone ever had to grind down an engine shaft to fit before?

Grizz03

RCTalk Qualifier

- Messages

- 165

- Reaction score

- 117

- RC Driving Style

- Bashing

I don't see why it wouldn't work.

A little trick to help save you from possible aggravation from deformed threads where you ground the shaft down is to put on a nut. It will help clean up the threads making it easier to install the clutch shaft back on. You would put a nut on the shaft, grind down the shaft to the length needed, and then when removing the nut it will help clean up the threads on the end of the shaft. Sometimes the new engines come with a nut holding the driver washer/spacer. If not I believe the crankshaft thread is a M5-0.8

A little trick to help save you from possible aggravation from deformed threads where you ground the shaft down is to put on a nut. It will help clean up the threads making it easier to install the clutch shaft back on. You would put a nut on the shaft, grind down the shaft to the length needed, and then when removing the nut it will help clean up the threads on the end of the shaft. Sometimes the new engines come with a nut holding the driver washer/spacer. If not I believe the crankshaft thread is a M5-0.8

Similar threads

F

- Replies

- 0

- Views

- 246

F