HPI-Killer

Axial Axle Twisting Guru

Supporter

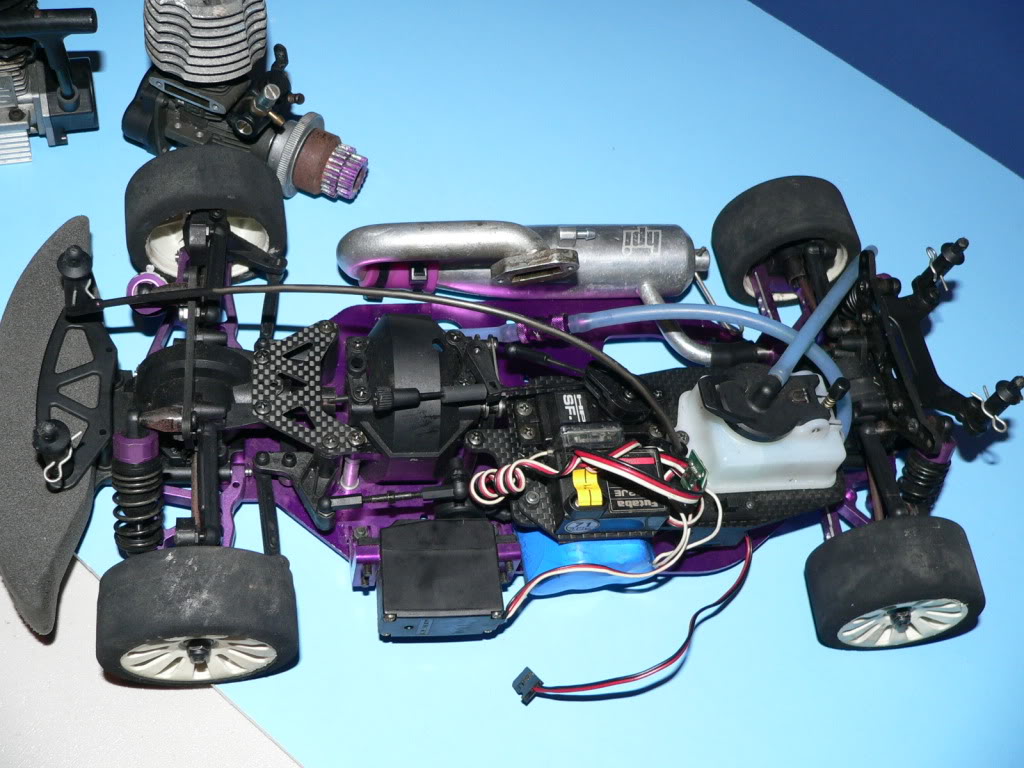

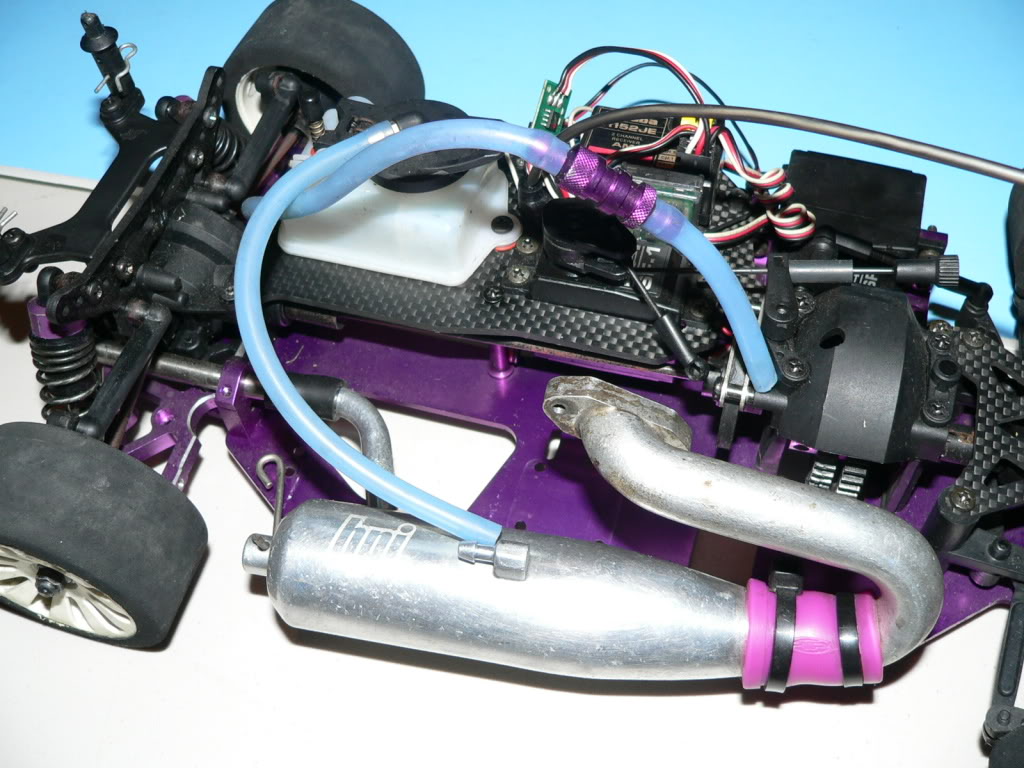

Just got my used HPI RS4 3 with the stage D kit and lookin pretty good with so many parts and a team bag on wheels and a pull out handle like an airport bag, also came the 2 motors + too much to list. Curious as if anyone knows what they are and whats better? I figured V 15 was a .15. Input please. Paid $100 shipped for everything

Thanks guys

Also a red/black wire with a connector comes off the on/off switch, what is this? Above that there are exposed wires on the reciever, one which has a little chip with a red light, connected the battery I know, but what does the red light indicate? PS-How do I get that blasted battery pack out?

Also was wet one time (all electronics and such work still)but it got a tad rust on some of the metal parts,is there any way I can "freshen" up the moving/rotating/sliding parts to lubricate it back to new or w.e

Thanks guys

Also a red/black wire with a connector comes off the on/off switch, what is this? Above that there are exposed wires on the reciever, one which has a little chip with a red light, connected the battery I know, but what does the red light indicate? PS-How do I get that blasted battery pack out?

Also was wet one time (all electronics and such work still)but it got a tad rust on some of the metal parts,is there any way I can "freshen" up the moving/rotating/sliding parts to lubricate it back to new or w.e

Last edited:

PS- These engines reak of old fuel bad

PS- These engines reak of old fuel bad