Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

links, including eBay, Amazon, and others.

More options

Who Replied?- Messages

- 50

- Reaction score

- 73

- RC Driving Style

- Bashing

- Racing

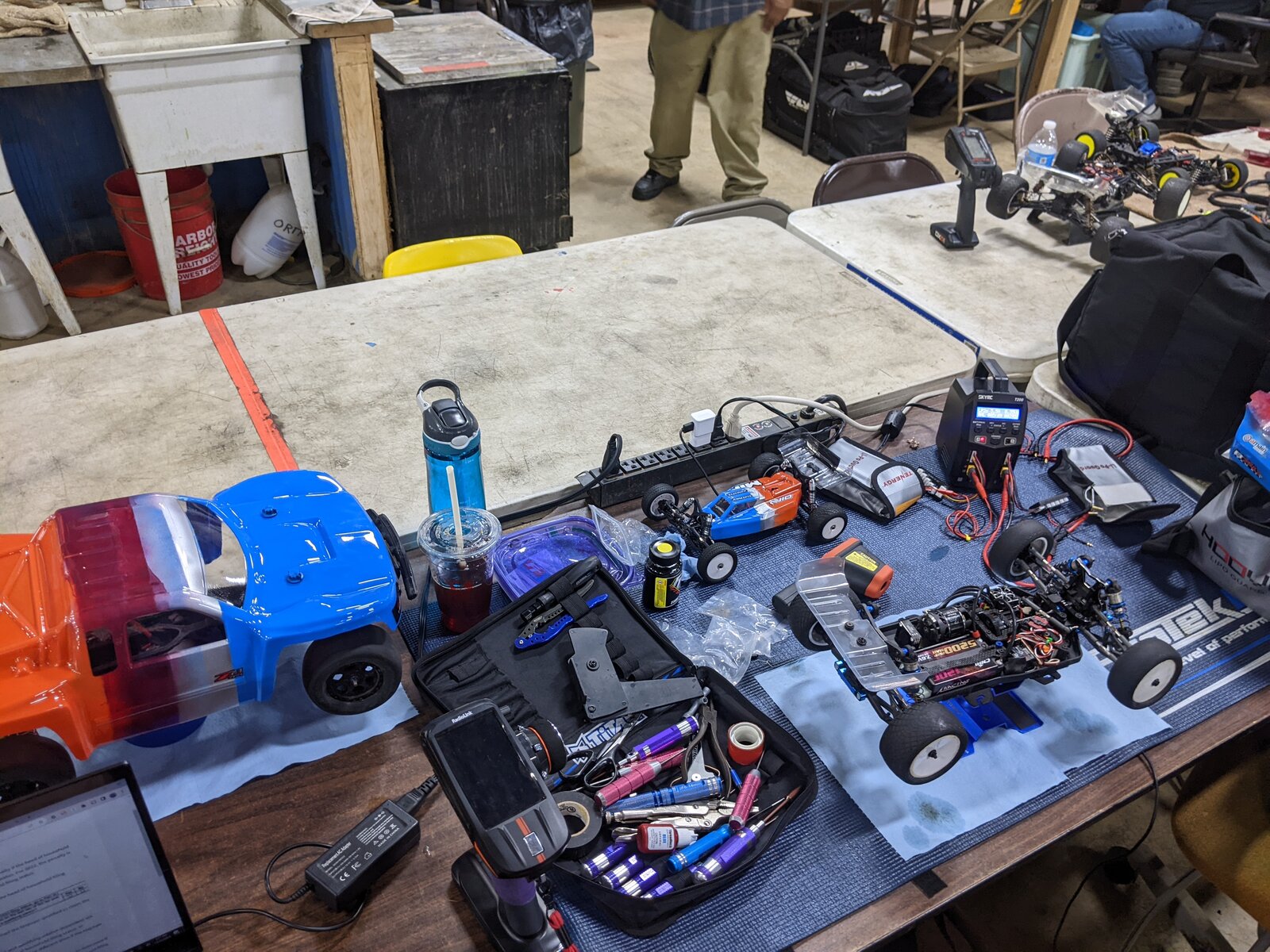

I Wish I had stuff this nice!!This is the 2.0 thread of my AE B74.1D 4wd race buggy. On this thread you will see what I change from the stock set up, testing and tuning to the car and some race/practice videos.

Current electronics:

Hobbywing XR10 Pro 160A ESC (Legacy version)

Hobbywing V10 G4 13.5 Stock motor

Xpert 4000 series high speed servo

Maclan 7.6 LiHV 6100 packs

Other parts:

Protek Aluminum Motor fan

Jconcepts Ellipse silver compound F+R

Associated offset wheels from the B64

Factory Team 20mm aluminum servo horn

Protek RC 20T 3.17bore 48p pinion gear (will change in the future, probably anywhere from 25-28)

Stock kit spur (78t 48p)

Using Radiolink Rx/Tx (Radiolink RC4GS V3) (later down the road I will upgrade to a mid range futaba or sanwa) (Futaba 4pm, Sanwa Mt44)

And that is it on what I have in the car right now. Later in the future I will post the following

Changes to kit set up

Testing

Tuning

Videos of racing and practice

Happy RCing or Racing!View attachment 157616View attachment 157617View attachment 157618

Maybe you should concider new tires?

- Messages

- 5,960

- Reaction score

- 9,859

- Location

- Baltimore

- RC Driving Style

- Bashing

- Racing

- Crawling

- Scale Builder

- Thread starter

- #45

Was wrenching earlier today. Got the right bearings, front stub axle, and wheel hexes, thinking that, that was the problem, nope it was the hub as the plastic was warped so thats why I was going through those bearings and having lots of play. I had a spare hub, but turned out it was for the right not the left. I'm gonna call the LHS to see if she has the part in-stock before I go down to the track tomorrow, if not, i won't since I won't be able to race. Funny thing is I broke the same hub and same side at Beach RC a few months ago. So we will see how it all goes tomorrow. Next time I will be able to go down and race is xmax break.

Was it the inner bearing in the steering knuckle? Mine were slightly oval and harmed the bearings. I reamed them round and the problem is gone now.

- Messages

- 5,960

- Reaction score

- 9,859

- Location

- Baltimore

- RC Driving Style

- Bashing

- Racing

- Crawling

- Scale Builder

- Thread starter

- #47

It was fine when I installed the replacement one at Beach RC. Noticed I blew the bearing and it had play at the track last week. She has it in stock so I'll replace it again, and if it does happen again I'll do what you did.

WickedFog

Starter of too many projects

Supporter

Excellence Award

Hospitality Award

Rig of the Month Winner

Build Thread Contributor

- Messages

- 14,939

- Reaction score

- 21,145

- Location

- Terre Haute, IN

- RC Driving Style

- Bashing

- Crawling

- Scale Builder

Almost all plastic steering knuckles I have seen have oval bearing journals. The part shrinks in one axis after releasing from the mold due to the design that must be maintained to make them. Putting the bearing in will typically reshape them back to as they were in the mold. How far out of round were your journals?View attachment 175443

Was it the inner bearing in the steering knuckle? Mine were slightly oval and harmed the bearings. I reamed them round and the problem is gone now.

One thing I do is heat them up, install the bearing, then shock them in cold water to lock them into shape.

The outer bearing races are too flimsy to push the plastic of the B74 knuckle into shape. The ovality was 0.16 mm which is a huge deviation in this context. The previous post shows the major diameter. Below is the minor diameter.Almost all plastic steering knuckles I have seen have oval bearing journals. The part shrinks in one axis after releasing from the mold due to the design that must be maintained to make them. Putting the bearing in will typically reshape them back to as they were in the mold. How far out of round were your journals?

One thing I do is heat them up, install the bearing, then shock them in cold water to lock them into shape.

I also tried boiling the knuckles with the rear end of a 10 mm drill bit shoved into the bearing recess to give it shape. Dunked it into comd water to set the new shape. No effect at all.

Finally, I made a reamer out of the valve nut of a bicycle inner tube. It happened to be the right size and took off just enough material to fix the problem.

Minor diameter after reaming. Not perfect but made all the difference.

- Messages

- 5,960

- Reaction score

- 9,859

- Location

- Baltimore

- RC Driving Style

- Bashing

- Racing

- Crawling

- Scale Builder

- Thread starter

- #51

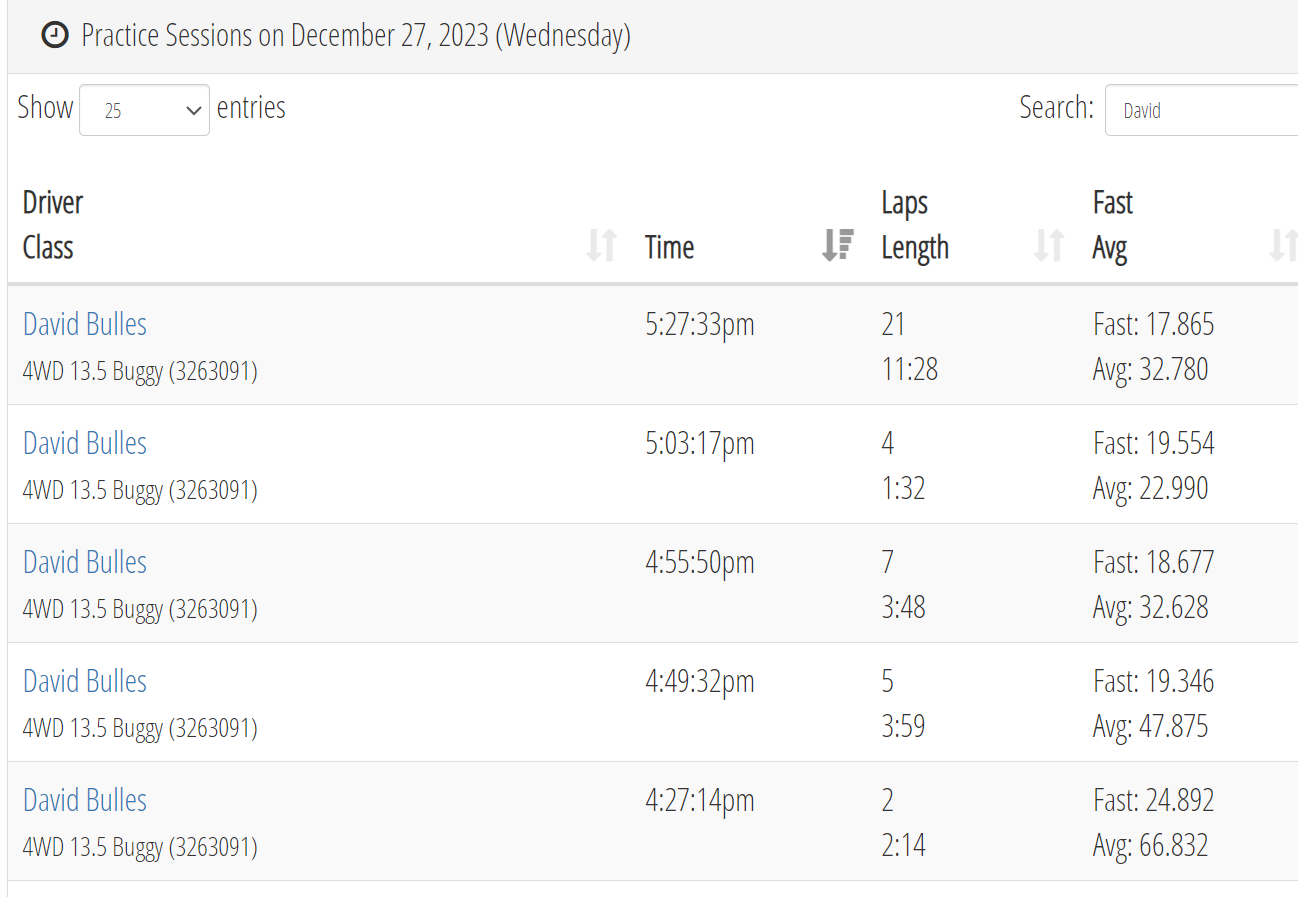

Race report from last night @ The Track - indoor sealed dirt "Clay" which is blue groovie.

Got there around 3/3:30. Had some practice with the Buggy. Didn't ran the slash and mini b. Might just bring one car each time as I don't have time to run other cars.

The tires are worn down to slicks now. New compound is working very well. and the tires are pretty sticky. I did replace that front hub. Hopefully not to have that issue again.

Racing started at 6.

Thanksgiving dinner was served. Pretty good foods. Posted in the "Whatcha Eating" thread.

I think clay is more better than carpet. - Change my mind.

Yes clay is lower traction, your cars get somewhat dusty/dirty. But there is more prep. And with that prep, I feel like your actually racing. Not to mention the formed dirt jumps make it more offroad style. As with carpet, there is constant high traction, no tire prep, but your cars stay nice and clean for the most part. Carpet is only known for offroad due to the ramps, as the actual carpet is on a flat surface. any comments on that? Anyone agree?

any comments on that? Anyone agree?

On to my actual race report, lol.

I'm doing alright. Last Monday I went down for practice so that helped me. I also think that Beach RC back in the summer also helped me, as I did get some advice from my uncle, and the pro drivers down there. One guy, David Olsen? Big name, heard of him? Kinda popular overhere on the east coast.

At this track, we did 3 rounds of qualifying so it was a bit longer. I'm used to 2 rounds of qualifying and less people. We had 34 drivers that night. Pretty average for a Wednesday night with looking at the past race results on Live RC, but this was Wednesday before Thanksgiving so.

Ill skip my qualifiers, cause who wants to hear all of that.

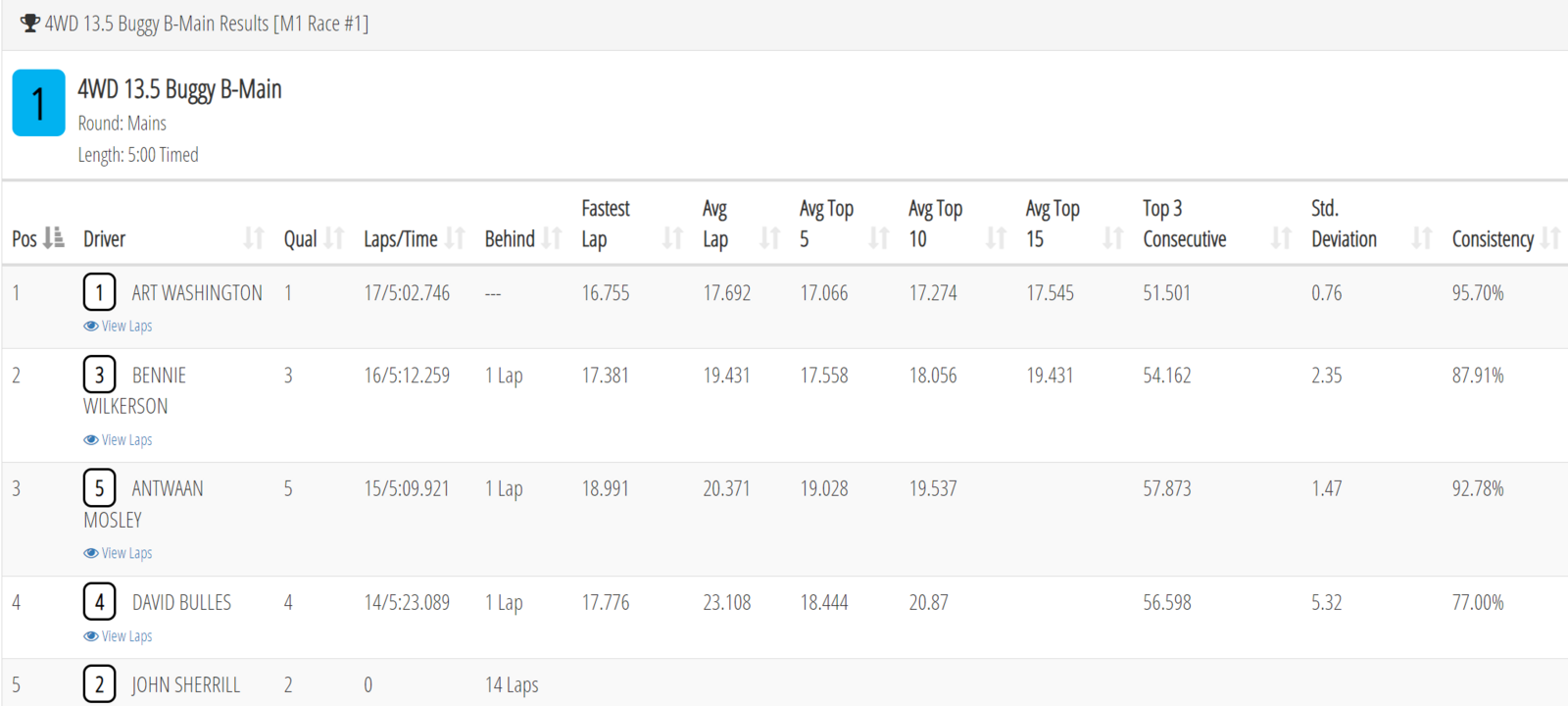

B Main: Started in 4th, ended in 4th. Fast lap of 17.77. Fastest lap I did at that track so far. Average of an 23.10. 77% Consistency. I was at 88 and 86 in the quals, I think radio issues and crashing were the problems. But not that bad as a first race at that track, and a second full club race night at a indoor dirt track.

My radio issues I had been having are posted in this thread: https://www.rctalk.com/forum/threads/radiolink-anyone.140122/post-1404133

Here are some videos from last night! My roddie didn't get video of my B Main tho. I would have did my phone head strap thing again but the angle would be super off like always.

Here are my tires now which traction has improved. Maybe / Maybe not. Overall I feel like it improved but some spots of the track there is traction roll city, and no traction at-all.

Packed house last night

And discovered that 1 singular fiber of the rear shock tower is almost chipped off. Some CA glue should fix that.

With the taction compound, after a race I come off the track, marshall the next race (6 minutes ideally but only 5 for the race) I change out batteries and re-apply compound for the next race which would be in about 20 or 30 minutes since I am only running 1 Class. I try to get the compound all dry and into the tire before the race. But what I have been seeing is that there is a little spot still wet, its all good tho.

I haven't been cleaning off my tires tho. I been cleaning the tires when I get home or the next day. Using normal water, and a old rag, and dry with a shop towel. I seen people use simple green but I think it might harm the tires? Simple green might be a easier way to clean tires before re-applying compound tho.

Since I like my cars to be mostly clean, I been carrying around a old tooth brush I use to clean off the car, and spread out the compound on the tires.

Got there around 3/3:30. Had some practice with the Buggy. Didn't ran the slash and mini b. Might just bring one car each time as I don't have time to run other cars.

The tires are worn down to slicks now. New compound is working very well. and the tires are pretty sticky. I did replace that front hub. Hopefully not to have that issue again.

Racing started at 6.

Thanksgiving dinner was served. Pretty good foods. Posted in the "Whatcha Eating" thread.

I think clay is more better than carpet. - Change my mind.

Yes clay is lower traction, your cars get somewhat dusty/dirty. But there is more prep. And with that prep, I feel like your actually racing. Not to mention the formed dirt jumps make it more offroad style. As with carpet, there is constant high traction, no tire prep, but your cars stay nice and clean for the most part. Carpet is only known for offroad due to the ramps, as the actual carpet is on a flat surface.

On to my actual race report, lol.

I'm doing alright. Last Monday I went down for practice so that helped me. I also think that Beach RC back in the summer also helped me, as I did get some advice from my uncle, and the pro drivers down there. One guy, David Olsen? Big name, heard of him? Kinda popular overhere on the east coast.

At this track, we did 3 rounds of qualifying so it was a bit longer. I'm used to 2 rounds of qualifying and less people. We had 34 drivers that night. Pretty average for a Wednesday night with looking at the past race results on Live RC, but this was Wednesday before Thanksgiving so.

Ill skip my qualifiers, cause who wants to hear all of that.

B Main: Started in 4th, ended in 4th. Fast lap of 17.77. Fastest lap I did at that track so far. Average of an 23.10. 77% Consistency. I was at 88 and 86 in the quals, I think radio issues and crashing were the problems. But not that bad as a first race at that track, and a second full club race night at a indoor dirt track.

My radio issues I had been having are posted in this thread: https://www.rctalk.com/forum/threads/radiolink-anyone.140122/post-1404133

Here are some videos from last night! My roddie didn't get video of my B Main tho. I would have did my phone head strap thing again but the angle would be super off like always.

Packed house last night

And discovered that 1 singular fiber of the rear shock tower is almost chipped off. Some CA glue should fix that.

With the taction compound, after a race I come off the track, marshall the next race (6 minutes ideally but only 5 for the race) I change out batteries and re-apply compound for the next race which would be in about 20 or 30 minutes since I am only running 1 Class. I try to get the compound all dry and into the tire before the race. But what I have been seeing is that there is a little spot still wet, its all good tho.

I haven't been cleaning off my tires tho. I been cleaning the tires when I get home or the next day. Using normal water, and a old rag, and dry with a shop towel. I seen people use simple green but I think it might harm the tires? Simple green might be a easier way to clean tires before re-applying compound tho.

Since I like my cars to be mostly clean, I been carrying around a old tooth brush I use to clean off the car, and spread out the compound on the tires.

Last edited:

Buggies on carpet tracks are just touring cars with jumps in my opinion. If carpet is the surface we have, I’d get rid of jumps and run a proper on-road vehicle.

Our local off road track is astroturf but there are artificial bumps placed underneath the material so you have to address it with setup choices and line choices. I quite like it.

The rear shock tower doesn’t look alarming to me. A drop of CA will be good for peace of mind, I doubt it would delaminate beyond the upper shock mounts anyway. Keep those screws tight but not overtightened.

Our local off road track is astroturf but there are artificial bumps placed underneath the material so you have to address it with setup choices and line choices. I quite like it.

The rear shock tower doesn’t look alarming to me. A drop of CA will be good for peace of mind, I doubt it would delaminate beyond the upper shock mounts anyway. Keep those screws tight but not overtightened.

- Messages

- 649

- Reaction score

- 964

- Location

- Paris somewhere

- RC Driving Style

- Bashing

- Racing

- Scale Builder

*ConsiderMaybe you should concider new tires?

- Messages

- 649

- Reaction score

- 964

- Location

- Paris somewhere

- RC Driving Style

- Bashing

- Racing

- Scale Builder

Sir auto correct the 3rd

- Messages

- 5,960

- Reaction score

- 9,859

- Location

- Baltimore

- RC Driving Style

- Bashing

- Racing

- Crawling

- Scale Builder

- Thread starter

- #57

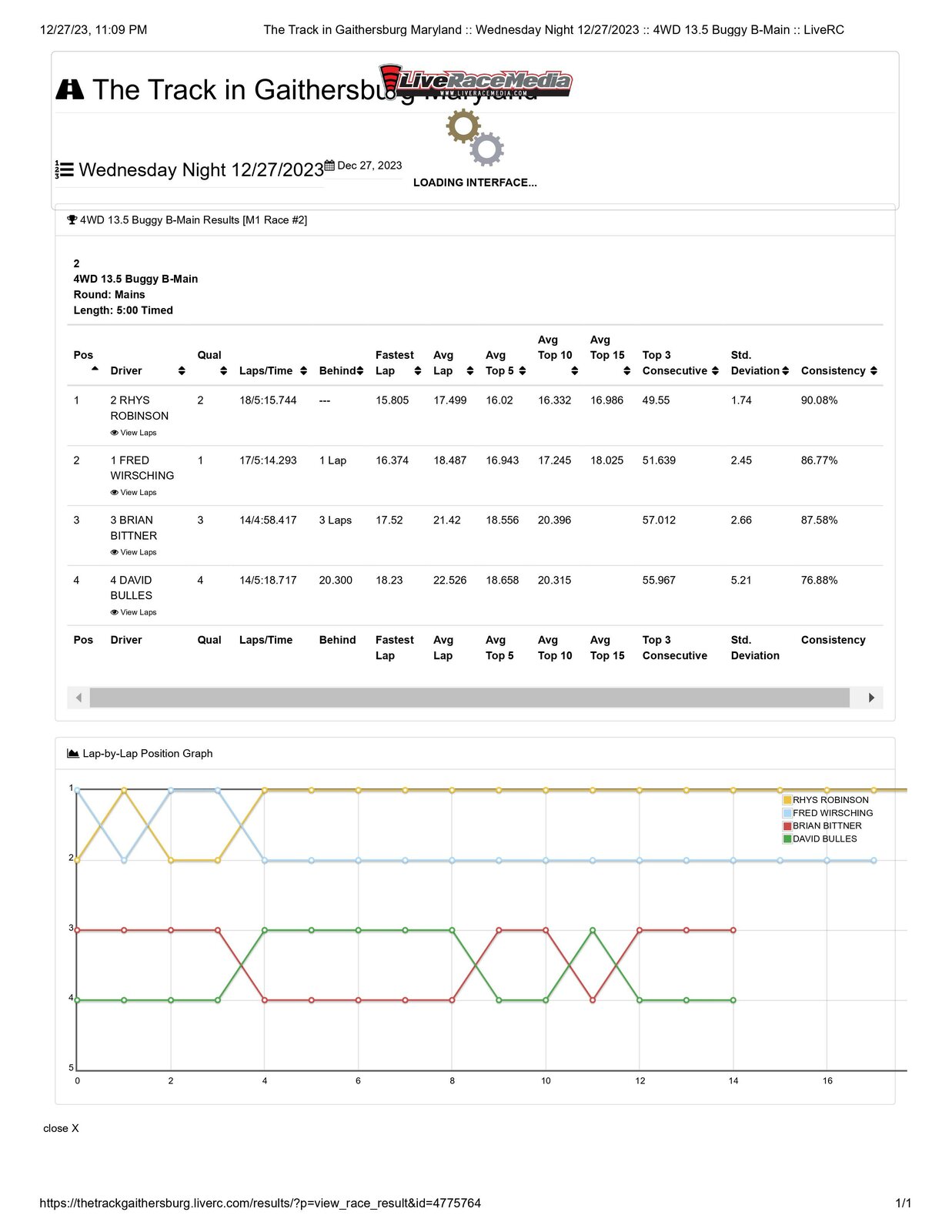

Another club race day @ The Track

4WD 13.5 Buggy with the B74

For practice, had some issues with the left front axle / hex. If I tightened the nut all the way, the wheel would lock up. Replaced the hex and pin, and wheel nut, still did it. Put some red and tacky grease on the inner part of the hub where the drive cup retainer sits, and some grease on the axle pin, new wheel nut, and is working good and smoothly again.

3 rounds of qualifying and 1 main (1 allowed bump)

In Q2 the wheel nut backed out and wheel got sent in the air. I was only 4 laps in.

(After that qualifier I got a spare wheel nut and loctite it on. Let it dry until the next race)

In Q3 I managed to get from 5th to 4th and I got 4th in the B Main.

Tires are JConcepts ellipse that have 8 track days (3 of those are race days) and still going good. Been using FDJ Yellow dot and is working good. Sometimes had some traction rolling, but not a huge issue. Thought I was going to get new tires today, but decided not to as they are still good. Thinking 2 more race days before they are gone. Once I get new tires, going to get Smoothie 2's as they are the go to tire, but are pretty pricey and always on backorder for them being super popular. Might even just get a replacement set of ellipses and run those to get the same results, but Smoothie 2's are the go to.

Earlier for practice, brought the slash. Got to get the gear mesh and slipper set correctly to get it to run better, but 2wd SCT on the track aint no good, has to be 4wd to get grip around the corners. Its pretty good on carpet though.

Had issues with the RC8X radio so deciding to get rid of it and just use my trusty 4GS radio until I get either a NB4 from Flysky or a Futaba.

Getting better at indoor clay, coming from indoor carpet from the summer. Gotta find a good setup and tuner upper. And do something about my chassis protector thing.

Dunno when the next time I can go to a track is. Could be spring break down @ Beach RC in Myrtle Beach, or it can be the Factory Raceway in York PA for some carpet action.

So for now on, for clay tracks, ill only bring the buggy, but if I'm at a carpet track ill bring the slash and mini b, as that is what I originally had them set up for.

(Text copied from Facebook)

4WD 13.5 Buggy with the B74

For practice, had some issues with the left front axle / hex. If I tightened the nut all the way, the wheel would lock up. Replaced the hex and pin, and wheel nut, still did it. Put some red and tacky grease on the inner part of the hub where the drive cup retainer sits, and some grease on the axle pin, new wheel nut, and is working good and smoothly again.

3 rounds of qualifying and 1 main (1 allowed bump)

In Q2 the wheel nut backed out and wheel got sent in the air. I was only 4 laps in.

(After that qualifier I got a spare wheel nut and loctite it on. Let it dry until the next race)

In Q3 I managed to get from 5th to 4th and I got 4th in the B Main.

Tires are JConcepts ellipse that have 8 track days (3 of those are race days) and still going good. Been using FDJ Yellow dot and is working good. Sometimes had some traction rolling, but not a huge issue. Thought I was going to get new tires today, but decided not to as they are still good. Thinking 2 more race days before they are gone. Once I get new tires, going to get Smoothie 2's as they are the go to tire, but are pretty pricey and always on backorder for them being super popular. Might even just get a replacement set of ellipses and run those to get the same results, but Smoothie 2's are the go to.

Earlier for practice, brought the slash. Got to get the gear mesh and slipper set correctly to get it to run better, but 2wd SCT on the track aint no good, has to be 4wd to get grip around the corners. Its pretty good on carpet though.

Had issues with the RC8X radio so deciding to get rid of it and just use my trusty 4GS radio until I get either a NB4 from Flysky or a Futaba.

Getting better at indoor clay, coming from indoor carpet from the summer. Gotta find a good setup and tuner upper. And do something about my chassis protector thing.

Dunno when the next time I can go to a track is. Could be spring break down @ Beach RC in Myrtle Beach, or it can be the Factory Raceway in York PA for some carpet action.

So for now on, for clay tracks, ill only bring the buggy, but if I'm at a carpet track ill bring the slash and mini b, as that is what I originally had them set up for.

(Text copied from Facebook)

Last edited:

Helge's first language is not English, so you might consider cutting him some slack

You had the problem with a front wheel binding if you tightened the nut before, right? Are you sure the axle crush tube is not missing? The hex pressing against the inner race of the bearing should not cause anything to bind. The part number I mean is 92189. It allows you to sandwich everything together tightly without binding.

Whether the wheel hex clamps or not doesn’t make a difference, the clamping only prevents the hex from falling off when the wheel is removed.

I recommend lubricating the axle threads instead of using thread lock. It makes working on the car easier and you don’t have to wait for anything to cure or harden. Prevents wheel nuts from coming loose, too.

Whether the wheel hex clamps or not doesn’t make a difference, the clamping only prevents the hex from falling off when the wheel is removed.

I recommend lubricating the axle threads instead of using thread lock. It makes working on the car easier and you don’t have to wait for anything to cure or harden. Prevents wheel nuts from coming loose, too.