gandalfnz

RCTalk Addict

Hi

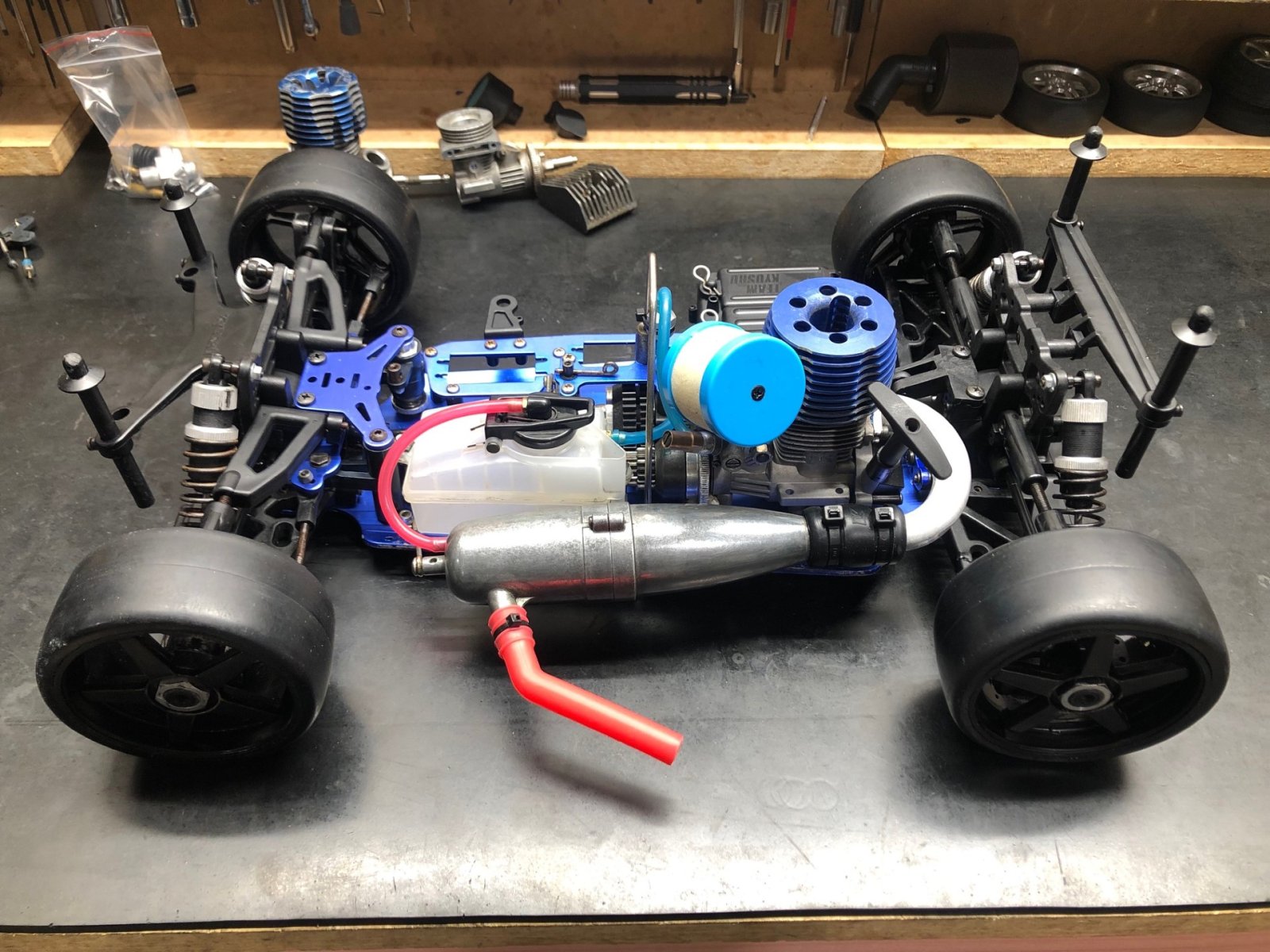

So, I got given this GT pretty much for free, as it was in terrible state.

In short, front end of the chassis was bent, front shock tower and bumper were broken, both spur gears striped, rusted driveshafts, broken pull start and a major one piston was was rotated by 180, which means it was hitting the crankshaft and was not able to start. Piston reversal was only done due to owner cleaning the engine before wanting to sell it, so luckily it was not ran like this.

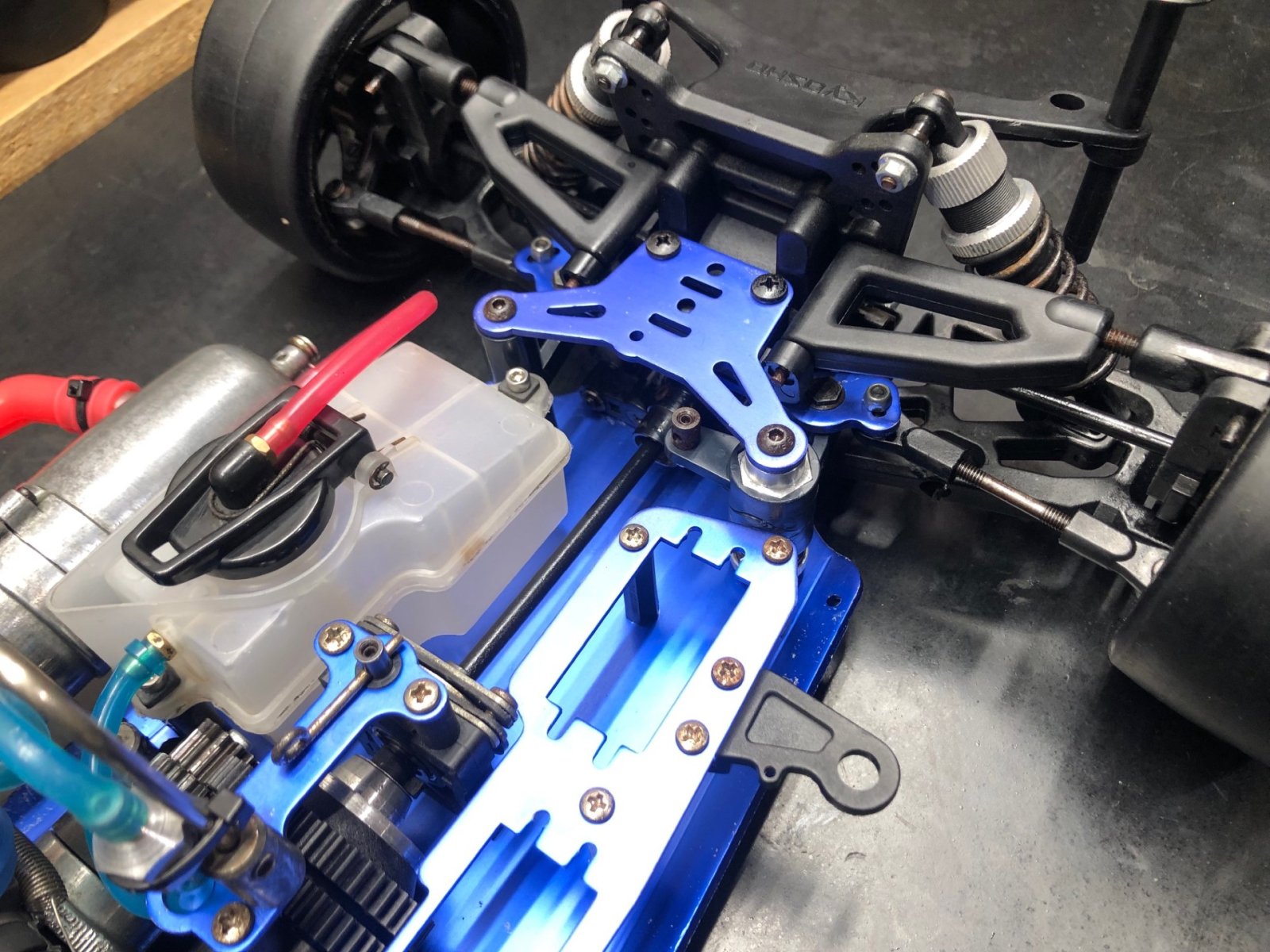

Sorted all these issues out, and the most interesting was the 2 speed gearbox, which is apparently the weakness point of GT1 and surprisingly GT2 as well.

From what I could find online, these strip spur gears like there is no tomorrow.

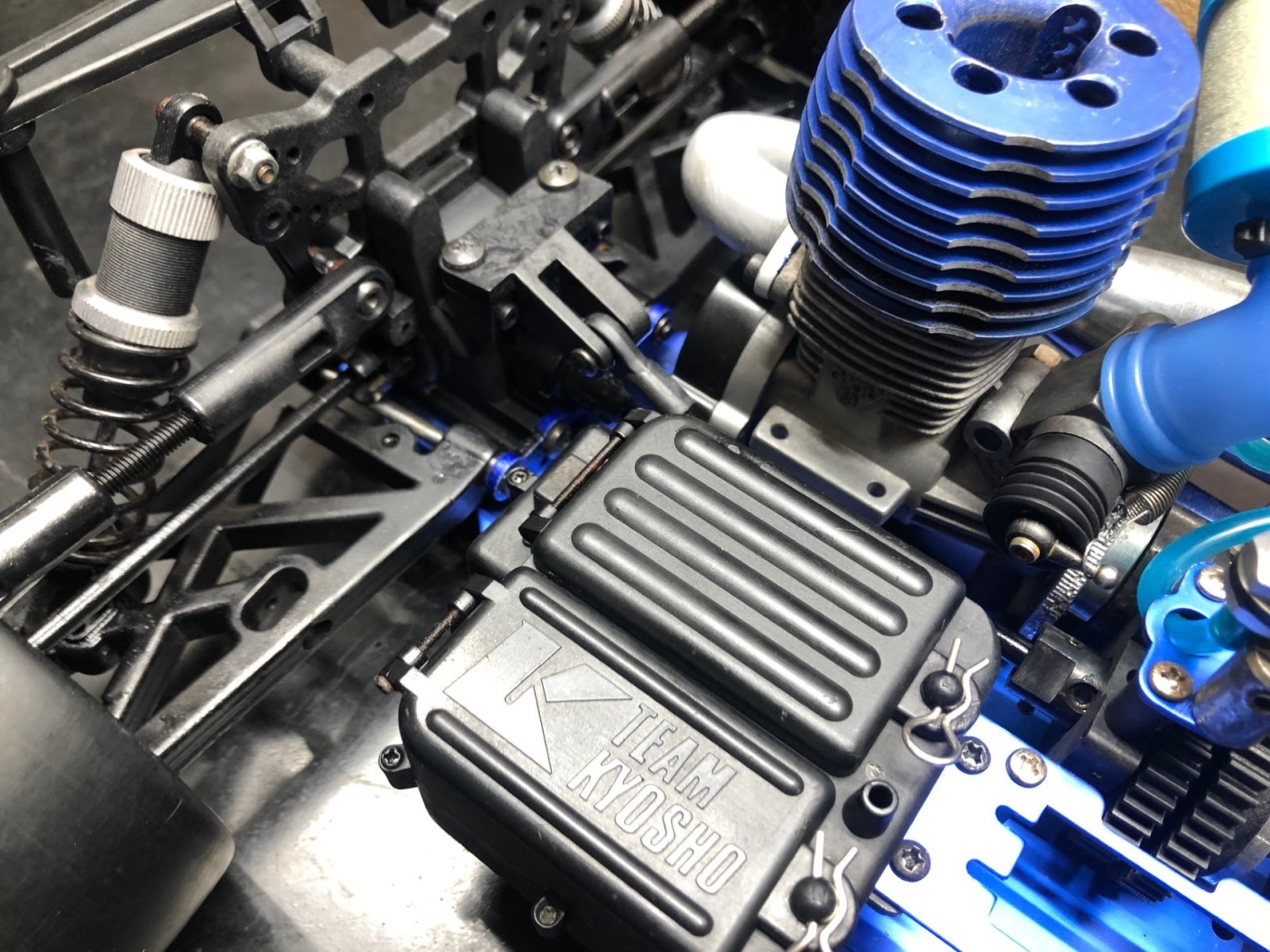

GT1 used the "PAWL" shifting system, which is poop to begin with, as we all know, basically I small metal claw pops up and hits a metal pin on the second spur, once sufficient RPM is reached. This works, but eventually the car stops shifting as either metal pin or claw is worn. Kyosho moved away from this design I believe on GT2 and GT3.

Spurs ending up being stripped I believe are because, Kyosho uses needle bearings in the clutch bell assembly, and these give a lot of side movement, couple this with not meshing the gears properly together and you have recipe for disaster. I have replaced the two needle bearings with ball bearings, but ended up using 5 or 6 of them, just slot them into the clutch bell housing.

In regards to the 2nd speed breaking/not engaging (see photo below), basically I found 3mm play between 1st and 2nd spur, this allows the 2nd spur to move away from the centrifugal clutch, which means the metal claw that comes up will hit only the side of the pin, rather than fully engage it, therefore breaking eventually.

I have shimmed the in between the spurs, and there is literally zero play now.

I think I may have improved on factory design with the above.

The whole car was stripped and cleaned, including the engine ultrasonic bathing, I am now just awaiting servos from Alixpress to finally give it a test. After this I will order the front shock tower and bumper set as well.

Engine seems to have good compression.

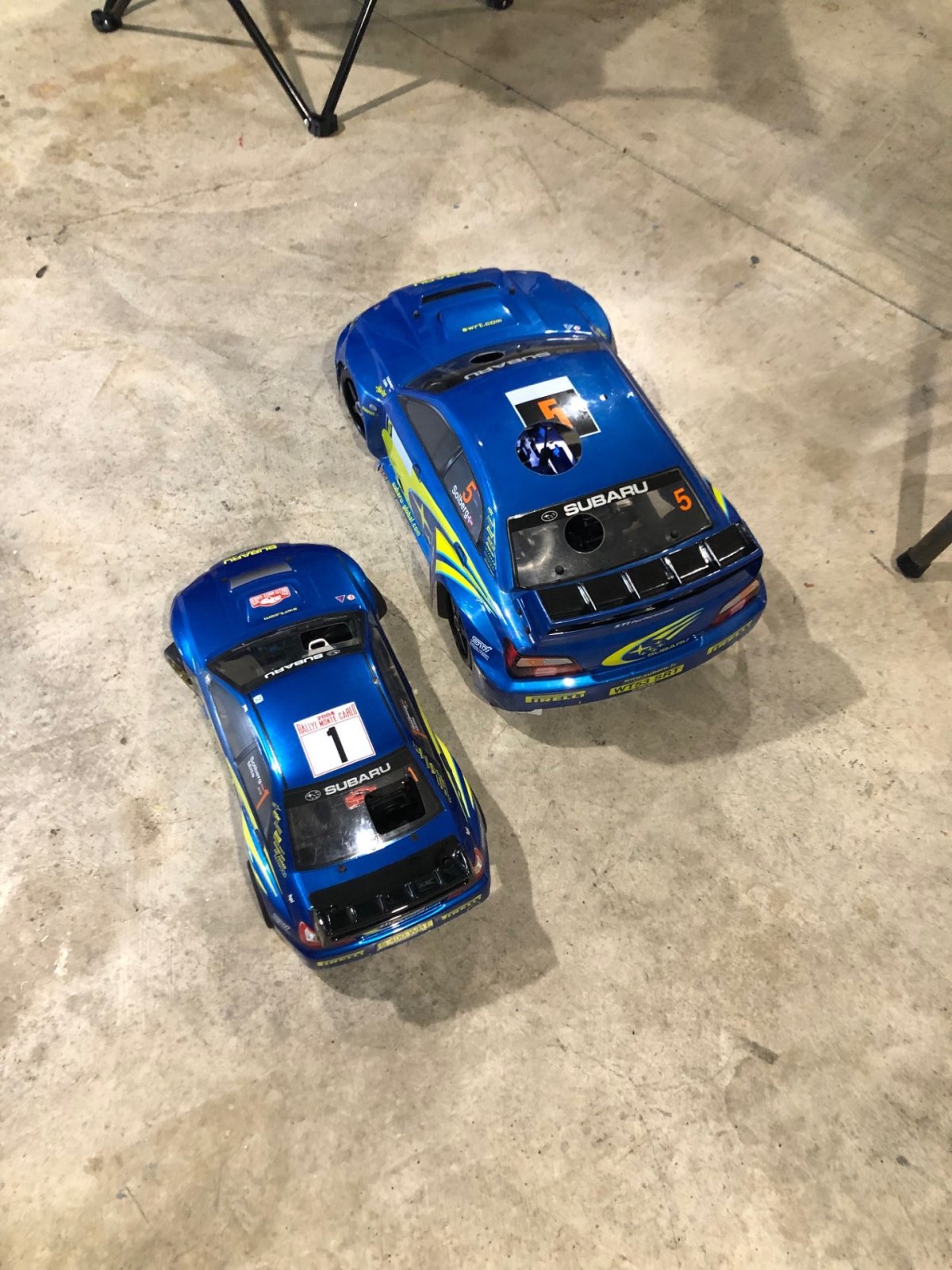

The car is huge, compared to my HPI RS4 Nitro Subaru.

Will post a video of it running later on, once all parts are here.

So, I got given this GT pretty much for free, as it was in terrible state.

In short, front end of the chassis was bent, front shock tower and bumper were broken, both spur gears striped, rusted driveshafts, broken pull start and a major one piston was was rotated by 180, which means it was hitting the crankshaft and was not able to start. Piston reversal was only done due to owner cleaning the engine before wanting to sell it, so luckily it was not ran like this.

Sorted all these issues out, and the most interesting was the 2 speed gearbox, which is apparently the weakness point of GT1 and surprisingly GT2 as well.

From what I could find online, these strip spur gears like there is no tomorrow.

GT1 used the "PAWL" shifting system, which is poop to begin with, as we all know, basically I small metal claw pops up and hits a metal pin on the second spur, once sufficient RPM is reached. This works, but eventually the car stops shifting as either metal pin or claw is worn. Kyosho moved away from this design I believe on GT2 and GT3.

Spurs ending up being stripped I believe are because, Kyosho uses needle bearings in the clutch bell assembly, and these give a lot of side movement, couple this with not meshing the gears properly together and you have recipe for disaster. I have replaced the two needle bearings with ball bearings, but ended up using 5 or 6 of them, just slot them into the clutch bell housing.

In regards to the 2nd speed breaking/not engaging (see photo below), basically I found 3mm play between 1st and 2nd spur, this allows the 2nd spur to move away from the centrifugal clutch, which means the metal claw that comes up will hit only the side of the pin, rather than fully engage it, therefore breaking eventually.

I have shimmed the in between the spurs, and there is literally zero play now.

I think I may have improved on factory design with the above.

The whole car was stripped and cleaned, including the engine ultrasonic bathing, I am now just awaiting servos from Alixpress to finally give it a test. After this I will order the front shock tower and bumper set as well.

Engine seems to have good compression.

The car is huge, compared to my HPI RS4 Nitro Subaru.

Will post a video of it running later on, once all parts are here.