Jamr

RCTalk Addict

Happy Friday everyone.

I am hoping to get some input from all the really inventive RC people out there.

I am trying to make the ultimate receiver box for people that have the room for it.

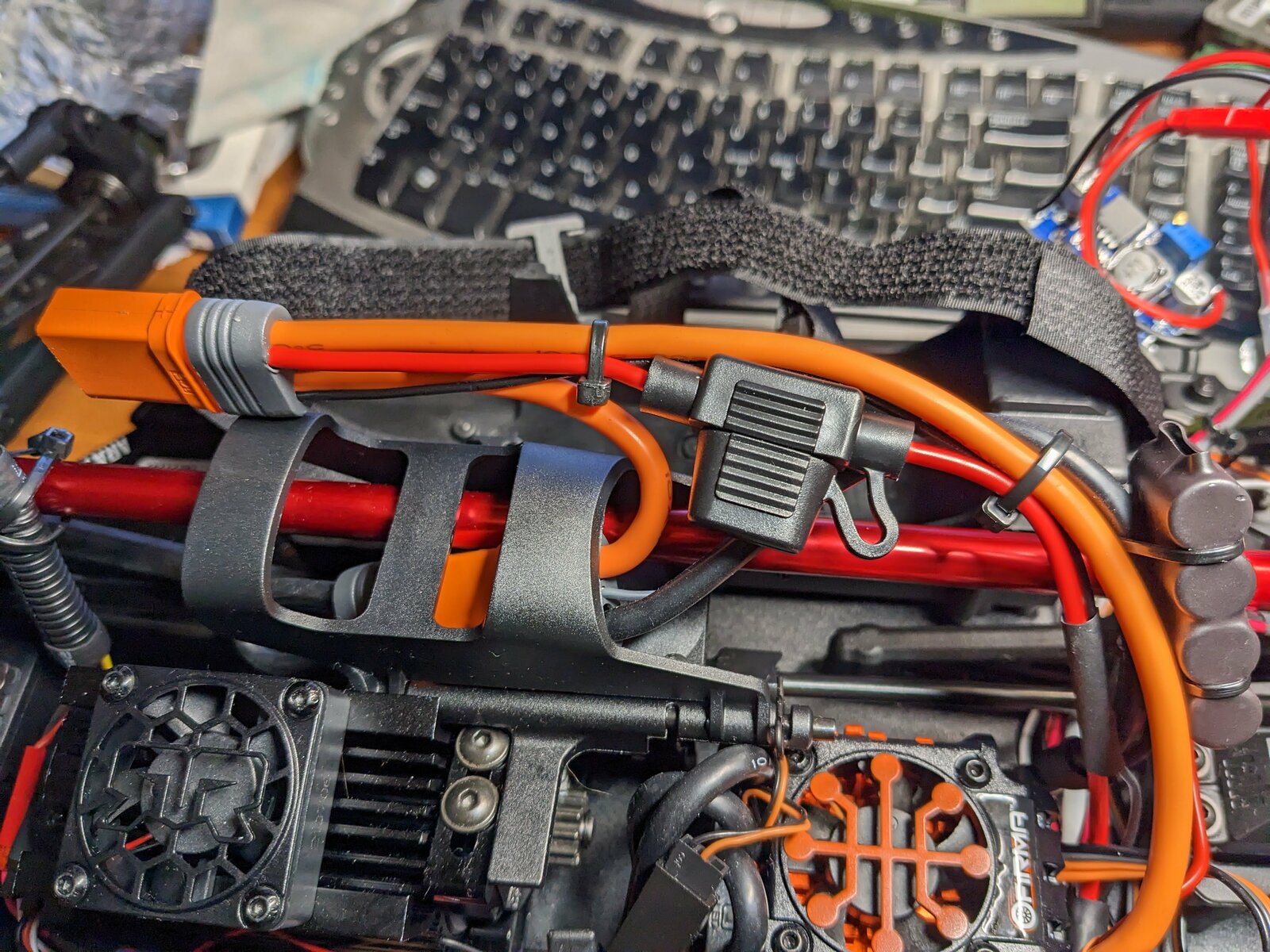

I like to separate the power requirements of my extra electronics (Lights, sounds) on my cars from the receiver and to the battery directly so they do not suck the power off of the receiver.

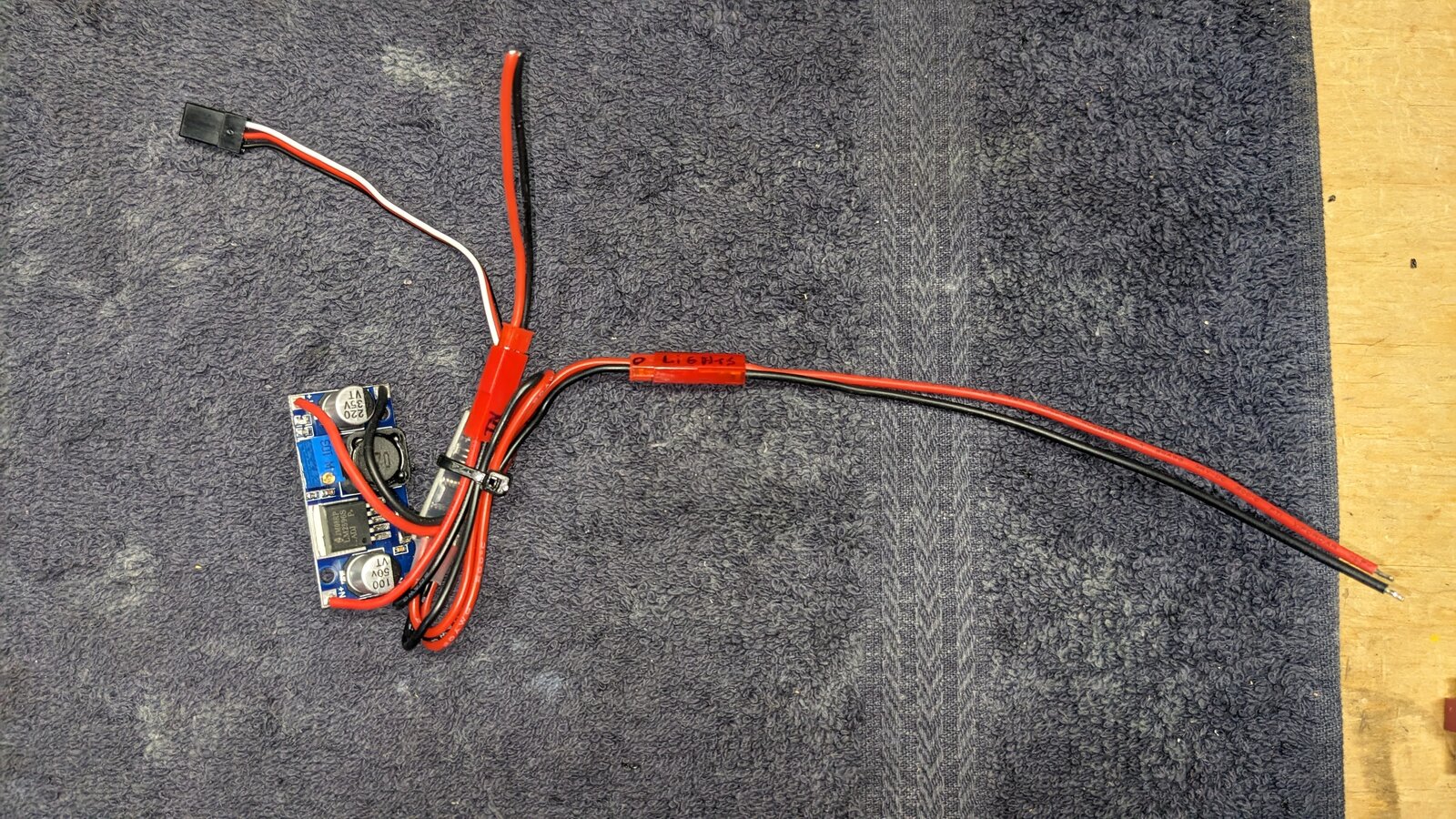

I also like to put a fuse holder and buck voltage converter on that fused battery line so that I do not have to run a resistor at every LED I use. Since batteries come in all different voltages I use a BVC to convert that voltage to a straight 6vdc or 3vdc. It just makes it easier when adding on other electronics later.

Bottom line; I have lots of electronic components I have to shove into the receiver box.

This is just the converter and a channel relay switch along with the receiver and a winch controller. I will also have to add a lighting box with the blinkers and such which I will have to put in a different box.

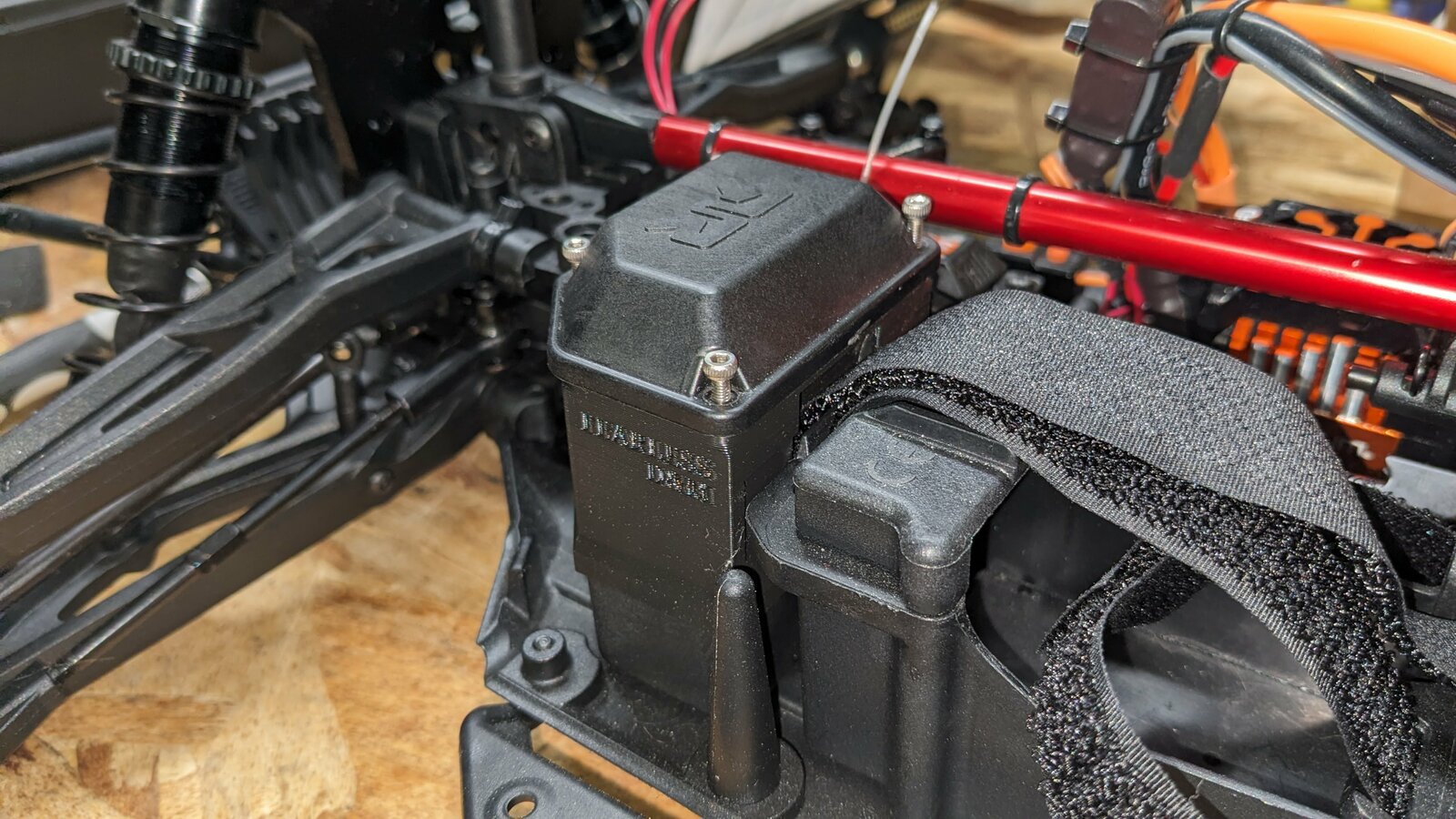

With this F450 I have a lot of room, so I am designing a receiver box that can hold all of this.

With my other cars, room was tight so I had to design extension boxes that extended the volume of the original box while still retaining the so called waterproofness of the box.

These work but are a pain to design due to the area I have to work with.

This new box is without constraints since I have so much room in this truck.

I had already switched out the receiver and the box to this but there just isn't enough room in that box so I have do make my own.

I looked on the various 3d print sites and could not find a decent waterproof one so I am designing one myself but I would like to get some input on what others might want in a receiver box.

Here is what I have so far.

It is about 55mm wide and 32mm tall and 33.5mm deep

Got a lot of ideas for water resistance like foam or a rubber band on the lid, beveled outer edge for water resistance, drip holes where the screws are, and a foam wall for the wire door.

I am also unsure of the antenna placement spot. Maybe all four sides and you break off the ones you don't want?

Also does anyone know of the exact ID and OD standard for an antenna tube? Is there a standard? I like the idea of having a antenna tube next to the receiver box that keeps the antenna out of harms way. Also placement of the antenna. Is it better to have the antenna high above the electronics? Maybe a holder on the lid if you have the vertical room?

Anybody else have any extra needs for a receiver box I am not thinking of?

Thanks for the ideas.

I am hoping to get some input from all the really inventive RC people out there.

I am trying to make the ultimate receiver box for people that have the room for it.

I like to separate the power requirements of my extra electronics (Lights, sounds) on my cars from the receiver and to the battery directly so they do not suck the power off of the receiver.

I also like to put a fuse holder and buck voltage converter on that fused battery line so that I do not have to run a resistor at every LED I use. Since batteries come in all different voltages I use a BVC to convert that voltage to a straight 6vdc or 3vdc. It just makes it easier when adding on other electronics later.

Bottom line; I have lots of electronic components I have to shove into the receiver box.

This is just the converter and a channel relay switch along with the receiver and a winch controller. I will also have to add a lighting box with the blinkers and such which I will have to put in a different box.

With this F450 I have a lot of room, so I am designing a receiver box that can hold all of this.

With my other cars, room was tight so I had to design extension boxes that extended the volume of the original box while still retaining the so called waterproofness of the box.

These work but are a pain to design due to the area I have to work with.

This new box is without constraints since I have so much room in this truck.

I had already switched out the receiver and the box to this but there just isn't enough room in that box so I have do make my own.

I looked on the various 3d print sites and could not find a decent waterproof one so I am designing one myself but I would like to get some input on what others might want in a receiver box.

Here is what I have so far.

It is about 55mm wide and 32mm tall and 33.5mm deep

Got a lot of ideas for water resistance like foam or a rubber band on the lid, beveled outer edge for water resistance, drip holes where the screws are, and a foam wall for the wire door.

I am also unsure of the antenna placement spot. Maybe all four sides and you break off the ones you don't want?

Also does anyone know of the exact ID and OD standard for an antenna tube? Is there a standard? I like the idea of having a antenna tube next to the receiver box that keeps the antenna out of harms way. Also placement of the antenna. Is it better to have the antenna high above the electronics? Maybe a holder on the lid if you have the vertical room?

Anybody else have any extra needs for a receiver box I am not thinking of?

Thanks for the ideas.