RC Addict

RCTalk VIP

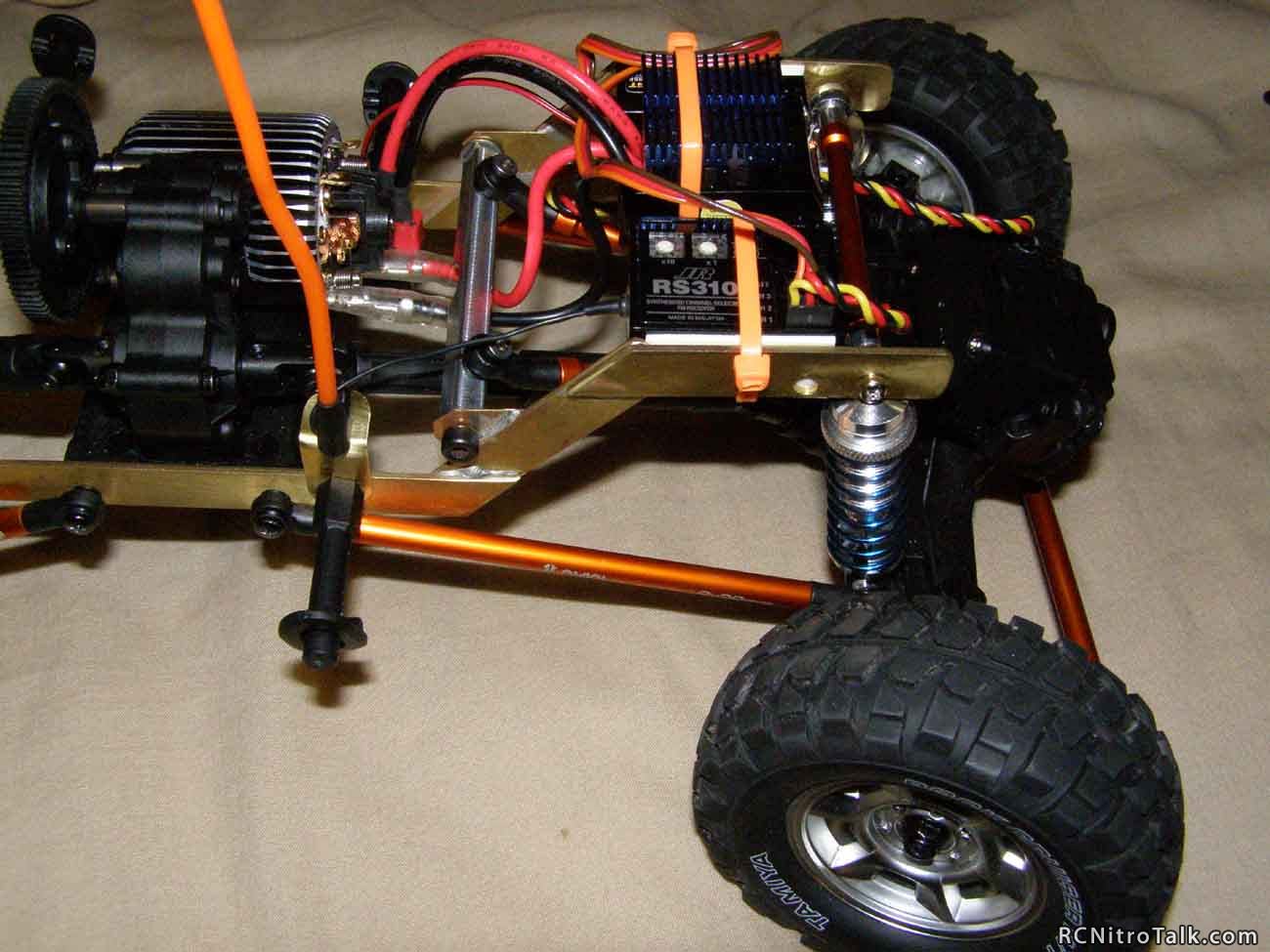

Just tuned into this one. Very impressive work!!!

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

Some still run shafty's for fun or as sportsmans. I havent for years though. Their not dead yet and probably wont be any time soon.

As long as your high clearance belly doesn't put too much angle on your shafts/yokes then you should be good to go.

Wow, you did a really serious build and it's first class. A real beauty.

You can use the standard body mounts. On this chassis it's a direct fit since the chassis is the same width as stock. On yours you can use threaded rod and drill through the side frame, nut and bolt on either side to set the width when the body post is threaded on.