I love my bump box, but it weighs as much as a whole RC car. I figured I could get the same torque from a single 3660 motor as its double 550 brushed motors, so I set about building the most superfluous brushless conversion ever.

A 10BL60 ESC with the fan removed, an arduino pro mini, and a 1400kv 3660 brushless motor are the guts of the conversion. The low KV is to match the RPM's of the original setup while running on 3S, which I measured at 5400 RPM fully charged. My conversion does just over 5000 RPM, which I am completely satisfied with.

The stated goal was to cut weight. The final weight is 2180g, down from 2860, a savings of 680g. Not bad, though the majority of that could be accomplished by just swapping out the NiMh cells for the lipo- but the Kyosho manual explicitly states that lipos are not recommended and may cause fire, so that's part of my excuse to do this conversion. Considering the stock bump box just dumps the battery voltage through the motors with a physical contactor, it's a big upgrade to longevity since now the contactor and power switch are exposed to sensing levels of current instead of the full amperage the motors are drawing.

I've coded for an arduino before, but this time I described my goals to ChatGPT and had it produce the code. One or two tweaks later and it ran perfectly.

It reads the push-plate and generates a PWM signal for the ESC. Seems simple enough, but of course it got more complicated as I added smooth transitions between PWM states, a button for reverse to calibrate the ESC, and a function to show the output state with the onboard LED.

Key details & challenges:

Reverse-engineering the tooth profile (FHT-3, compatible with HTD-3M) and finding a belt of the exact length (55 teeth) to work with 1 motor instead of 2.

Rewiring the ESC's power switch to the bump box's switch, including wiring in a "set" button.

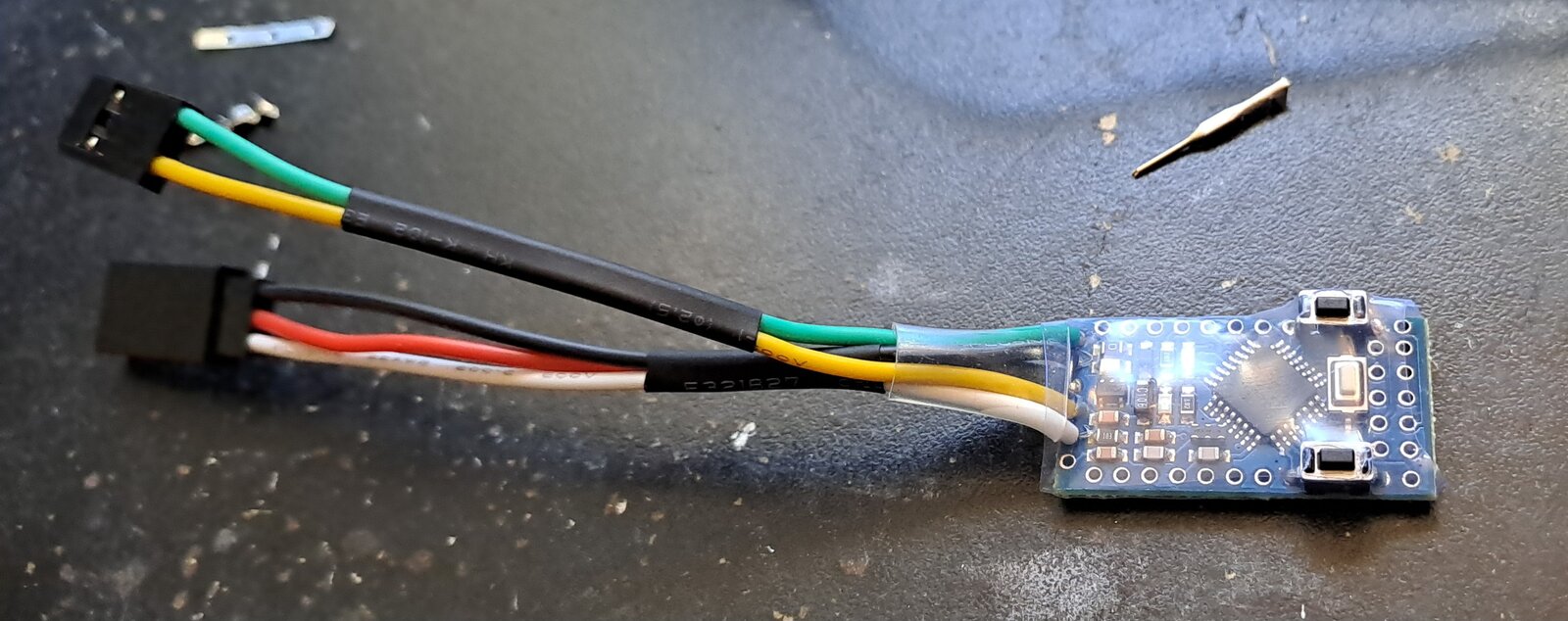

Incorporating a diode to drop the ESC's 6V to a level safe for the arduino (<5.5V) - I originally considered using the fan port voltage, which is directly from the battery, to the arduino's onboard regulator via the RAW pin, but I couldn't get the arduino to boot, only by giving it 5V on VCC. Using the BEC is cleaner anyway since that eliminates any connections to the fan port.

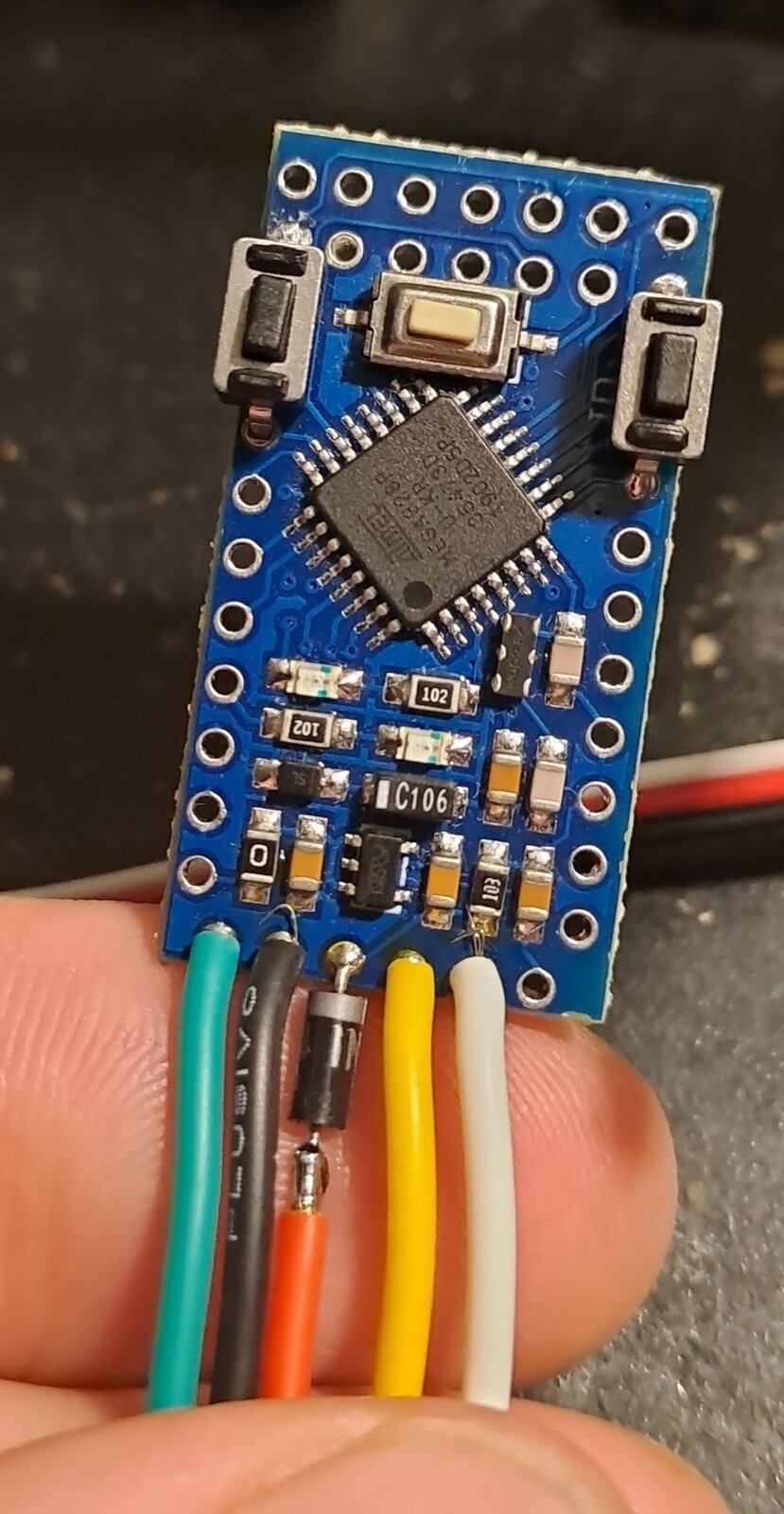

Incorporating forward & reverse test buttons directly onto the arduino.

Using the arduino's indicator LED to give visual confirmation of forward / reverse reads.

Using only the pins along the edge of the arduino for a very clean package & heat shrunk for that professional look:

The servo port goes to the ESC, and green/yellow reads the push-plate.

Videos to follow, preliminary tests have been promising. Fingers crossed that it doesn't suffer cogging issues.

A 10BL60 ESC with the fan removed, an arduino pro mini, and a 1400kv 3660 brushless motor are the guts of the conversion. The low KV is to match the RPM's of the original setup while running on 3S, which I measured at 5400 RPM fully charged. My conversion does just over 5000 RPM, which I am completely satisfied with.

The stated goal was to cut weight. The final weight is 2180g, down from 2860, a savings of 680g. Not bad, though the majority of that could be accomplished by just swapping out the NiMh cells for the lipo- but the Kyosho manual explicitly states that lipos are not recommended and may cause fire, so that's part of my excuse to do this conversion. Considering the stock bump box just dumps the battery voltage through the motors with a physical contactor, it's a big upgrade to longevity since now the contactor and power switch are exposed to sensing levels of current instead of the full amperage the motors are drawing.

I've coded for an arduino before, but this time I described my goals to ChatGPT and had it produce the code. One or two tweaks later and it ran perfectly.

It reads the push-plate and generates a PWM signal for the ESC. Seems simple enough, but of course it got more complicated as I added smooth transitions between PWM states, a button for reverse to calibrate the ESC, and a function to show the output state with the onboard LED.

Key details & challenges:

Reverse-engineering the tooth profile (FHT-3, compatible with HTD-3M) and finding a belt of the exact length (55 teeth) to work with 1 motor instead of 2.

Rewiring the ESC's power switch to the bump box's switch, including wiring in a "set" button.

Incorporating a diode to drop the ESC's 6V to a level safe for the arduino (<5.5V) - I originally considered using the fan port voltage, which is directly from the battery, to the arduino's onboard regulator via the RAW pin, but I couldn't get the arduino to boot, only by giving it 5V on VCC. Using the BEC is cleaner anyway since that eliminates any connections to the fan port.

Incorporating forward & reverse test buttons directly onto the arduino.

Using the arduino's indicator LED to give visual confirmation of forward / reverse reads.

Using only the pins along the edge of the arduino for a very clean package & heat shrunk for that professional look:

The servo port goes to the ESC, and green/yellow reads the push-plate.

Videos to follow, preliminary tests have been promising. Fingers crossed that it doesn't suffer cogging issues.

Last edited: