All I had him do was do a mild pinch on all three engines.

The engines are a SH28, Dynamite Mach 427, XTM 24.7.

The XTM had pinch still, but it was acting goofy late last season, so I figured why not send it in with the other two. The other two are a buddy's of mine and I'm getting this done for him. Neither of which would hold a tune, stalled constantly, ran hot and wouldn't idle hardly at all.

EDIT:

For those that missed it on the end, the cost is $25 (for pinch+priority ship) for each single sleeve/piston shipped if you do individuals. I did 3 at the same time, so it was $55 total.

This is a link to Ray's site: Ray A Racing Sleeve Service/Tooling

You can find the Resize Order form on his site. He responds pretty quickly to emails and is generally a decent guy to talk to.

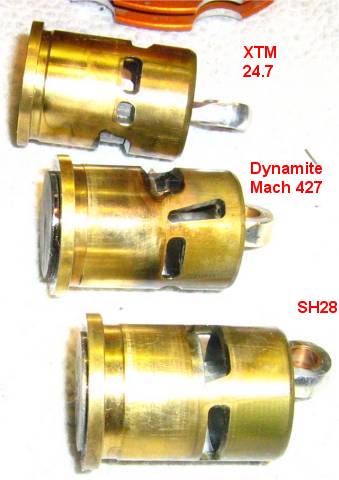

Pics of the before:

XTM 24.7:

SH28:

Dynamite Mach 427:

Photo's after:

XTM 24.7:

Mach 427:

SH28:

It seems he did a nice job on the XTM as I've put that engine back together and put it back in my buggy. With the GP out and it being lubed with ARO, it will turn over with the pull-start. Not easily... But I shouldn't have any issues re-breaking it in.

The other two engines were in far worse shape (as noted by Ray) and as you can see in the photo's. The piston would easily push out the end of the sleeve.

The "after" photo's are set where I could push the piston in as far as I could by hand (without a large amount of force), so you can see where the pinch now begins.

I'll post results after all engines are put back together and we get them broke-in again and running.

Just thought I'd share what can be done to an old tired piston/sleeve for $25 shipped (less per set the more you do at the same time).

The engines are a SH28, Dynamite Mach 427, XTM 24.7.

The XTM had pinch still, but it was acting goofy late last season, so I figured why not send it in with the other two. The other two are a buddy's of mine and I'm getting this done for him. Neither of which would hold a tune, stalled constantly, ran hot and wouldn't idle hardly at all.

EDIT:

For those that missed it on the end, the cost is $25 (for pinch+priority ship) for each single sleeve/piston shipped if you do individuals. I did 3 at the same time, so it was $55 total.

This is a link to Ray's site: Ray A Racing Sleeve Service/Tooling

You can find the Resize Order form on his site. He responds pretty quickly to emails and is generally a decent guy to talk to.

Pics of the before:

XTM 24.7:

SH28:

Dynamite Mach 427:

Photo's after:

XTM 24.7:

Mach 427:

SH28:

It seems he did a nice job on the XTM as I've put that engine back together and put it back in my buggy. With the GP out and it being lubed with ARO, it will turn over with the pull-start. Not easily... But I shouldn't have any issues re-breaking it in.

The other two engines were in far worse shape (as noted by Ray) and as you can see in the photo's. The piston would easily push out the end of the sleeve.

The "after" photo's are set where I could push the piston in as far as I could by hand (without a large amount of force), so you can see where the pinch now begins.

I'll post results after all engines are put back together and we get them broke-in again and running.

Just thought I'd share what can be done to an old tired piston/sleeve for $25 shipped (less per set the more you do at the same time).