I can spend some money. I would like to buy a Monster 4X4 hopefully i can carry it in the plane as fragile. Going to get a good customs tax too

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Losi LST 2 help please

- Thread starter Mattgen166790

- Start date

-

- Tags

- engine losi lst 2

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

links, including eBay, Amazon, and others.

More options

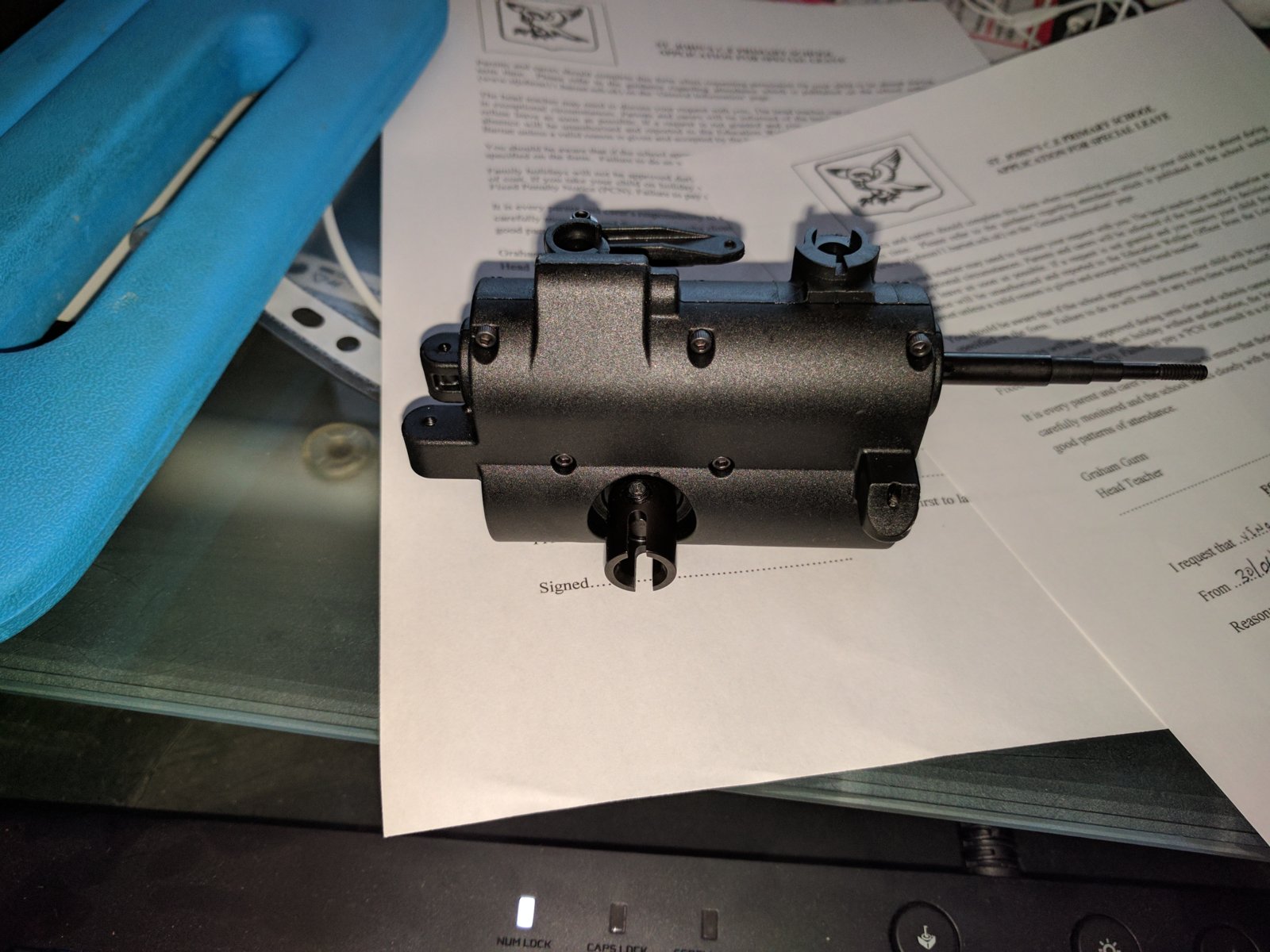

Who Replied?ok , So back to LST2 topic. I have got my new tranny from ebay(forward only). Now grease it with White lithum grease or not is my question? please help I read all the forums and the opinion is divided. Youtube videos shows that you need to break into the tranny by greasing it. But how bad the stock lube or whatever should be. I am bit scared to take it apart. But I will do it if i really had to.

Certified Mike

Hardcore RCTalk User

I really don't know what the recommended lube for those gears in that kit are so I don't know what to tell you.... BUT!!!

You need to be NOT AFRAID of taking ANY part of this kit apart!!! Certainly use caution! I recommend taking pictures so you know what things look like and for small things you may not notice. Use caution with tishings like one way bearings! They do in fact only work... ONE WAY! The way you keep track of them is by looking at the bearing itself. There is print, numbers stamped into the metal. It indicates which side to install it on. Make notes like, "bearing installed with print facing out". Also, pay attention to things like the washers used and where they are used, how they are stacked... When you disassemble this, have an exploded view of the trans already printed. Keep a length of paper towels laid out so as you remove each part, you have them laid out in the order they were removed. This makes reassembly so much easier! Save sure that you have already read thru the reassembly process so that if you have any questions or anything not understood, you will have already asked questions or at least know what you pay prticularly close attention to as you disassemble. Again, take pictures!!! Use your phone so you can be sure you've got good pics and you can zoom to see everything clearly BEFORE you move on! Good luck!!! ASK QUESTIONS!!!

The way you keep track of them is by looking at the bearing itself. There is print, numbers stamped into the metal. It indicates which side to install it on. Make notes like, "bearing installed with print facing out". Also, pay attention to things like the washers used and where they are used, how they are stacked... When you disassemble this, have an exploded view of the trans already printed. Keep a length of paper towels laid out so as you remove each part, you have them laid out in the order they were removed. This makes reassembly so much easier! Save sure that you have already read thru the reassembly process so that if you have any questions or anything not understood, you will have already asked questions or at least know what you pay prticularly close attention to as you disassemble. Again, take pictures!!! Use your phone so you can be sure you've got good pics and you can zoom to see everything clearly BEFORE you move on! Good luck!!! ASK QUESTIONS!!!

You need to be NOT AFRAID of taking ANY part of this kit apart!!! Certainly use caution! I recommend taking pictures so you know what things look like and for small things you may not notice. Use caution with tishings like one way bearings! They do in fact only work... ONE WAY!

The way you keep track of them is by looking at the bearing itself. There is print, numbers stamped into the metal. It indicates which side to install it on. Make notes like, "bearing installed with print facing out". Also, pay attention to things like the washers used and where they are used, how they are stacked... When you disassemble this, have an exploded view of the trans already printed. Keep a length of paper towels laid out so as you remove each part, you have them laid out in the order they were removed. This makes reassembly so much easier! Save sure that you have already read thru the reassembly process so that if you have any questions or anything not understood, you will have already asked questions or at least know what you pay prticularly close attention to as you disassemble. Again, take pictures!!! Use your phone so you can be sure you've got good pics and you can zoom to see everything clearly BEFORE you move on! Good luck!!! ASK QUESTIONS!!!

The way you keep track of them is by looking at the bearing itself. There is print, numbers stamped into the metal. It indicates which side to install it on. Make notes like, "bearing installed with print facing out". Also, pay attention to things like the washers used and where they are used, how they are stacked... When you disassemble this, have an exploded view of the trans already printed. Keep a length of paper towels laid out so as you remove each part, you have them laid out in the order they were removed. This makes reassembly so much easier! Save sure that you have already read thru the reassembly process so that if you have any questions or anything not understood, you will have already asked questions or at least know what you pay prticularly close attention to as you disassemble. Again, take pictures!!! Use your phone so you can be sure you've got good pics and you can zoom to see everything clearly BEFORE you move on! Good luck!!! ASK QUESTIONS!!! Once again a nut trouble. Set screw is hard as a rock. Surprisingly it's the new tranny. Is the hex Allen key wrong tool to use?

Certified Mike

Hardcore RCTalk User

I am using my phone. I can not see the screw clearly enough. One thing to be 100% sure of is that you have the correct size, that there is NO play and that there is NO damage to the tool you are using at all. What may appear to be only minimal damage on the tool can easily mean the difference between sucessful use and a stripped screw!

Hi I have uploaded more photos. I do not know what todo. I brought another brand new very well known tool set from Germany. Still the same day it doesn't like to come out. So couple of qualifications.

- Can I install drive train without loosing this nut?

- What are the options since hard to reach for dremel too I guess

Certified Mike

Hardcore RCTalk User

Is this screw the one sticking out of the outdrive cup? (where the dog bone goes in?)

Yes

Certified Mike

Hardcore RCTalk User

Yes, it does appear that you can install the trans without removing that screw... At some point it's likely you're going to have to work around that. It looks like you could take apart the other half of the trans where the other driver cup is and take it apart. When you're thru with that job, you'll end up with that drive cup stuck to a shaft that runs thru the trans. At that point, you can just slide the shaft out with the drive cup still stuck to it and replace those pieces... If the exploded view I am looking at is correct anyways.

https://www.google.com/search?clien...i30k1j0i67k1.4vcvoo-9WxE#imgrc=q1Nvq8hfdEN55M:

So part # B3127 and B3128 will have to be removed by taking all the gears, pins etc off of it after the trans cases are split and that shaft SHOULD slide out thru the bearing and case of you follow what I see in this diagram.

https://www.google.com/search?clien...i30k1j0i67k1.4vcvoo-9WxE#imgrc=q1Nvq8hfdEN55M:

So part # B3127 and B3128 will have to be removed by taking all the gears, pins etc off of it after the trans cases are split and that shaft SHOULD slide out thru the bearing and case of you follow what I see in this diagram.

Thanks a lot. I will install the transmission and i will try to run it for a bit. Hope the stock gear lube inside transmission is enough for now. I will try to open tranny up again a bit later. I just want to get it running first. So is my thin-inking right that the set screw is only used to hold the overdrive cup? hopefully the dog bone is not going to be loose or anything like that. its also pretty stuck on the other side. Maybe i need a some penetration oil to loosen these up before i attempt a retry again. I might try to purchase this dynamite hex key set so i know the tool should not be the problem,

https://www.horizonhobby.co.uk/p/dy...pCK63FrMk2ZyBvs9DNWtzTI9clR8Te4bNgaAv0t8P8HAQ

https://www.horizonhobby.co.uk/p/dy...pCK63FrMk2ZyBvs9DNWtzTI9clR8Te4bNgaAv0t8P8HAQ

Certified Mike

Hardcore RCTalk User

Unfortunately, whoever built this may have used red locktite or just overtightened that screw to the point where you would break just about any tool you use in There. You can try to use heat to loosen it but because of its proximity to the plastic, it seems likely you'll be melting the trans case. You could also try to drill out the screw. I would do that if an Allen wrench doesn't work.this will render the outdrive cup useless but it will save the shaft at least. Or, you can just avoid the whole thing and take it apart as I mentioned and replace the shaft and cup.

The driveshaft may end up being somewhat loose but it shouldn't be jammed tight inside the cup anyways.

The driveshaft may end up being somewhat loose but it shouldn't be jammed tight inside the cup anyways.

I believe that set screw is set in there with red loctite because when I did the FOC on my trans I was finally able to get one side off but not the other. bend a couple allen wrenches in the process.

As for tools, I'm personally sold on Team EDS tools. Hudy quality for half the price.

http://www.team-eds.com/default.asp

As for tools, I'm personally sold on Team EDS tools. Hudy quality for half the price.

http://www.team-eds.com/default.asp

Certified Mike

Hardcore RCTalk User

I would recommend trying to grab the Allen wrench with vise grips as close as you can to the bottom, leave as little as possible and use the vise grips to do the turning. At least if it snaps, it won't twist the whole wrench in the process. Heat will help if it is locktite... Just not real sure how to heat it excepting maybe to heat the Allen wrench and Let the heat work it's way thru the wrench and into the screw or to try and heat the cup. This is not typically how you would heat things to try and loosen them but I am thinking that if you did it this way, it would heat the locktite and help break it down. I would NOT use the same Allen wrench that you heated.

You can also use a cheap hex wrench to transfer heat. Heat the the tip of wrench red hot then put it in the screw and wait a few seconds for the heat to transfer to the part. Do that a few times, then use a good wrench to try and loosen the screw. Don't try using the red hot wrench as it will be destroyed by the heat and will just twist the tip off. It's only purpose is to let you get good heat to the screw/part to try and break the bond of the locktite/rust.

Sorry for the late reply, I was on holiday. With this new transmission without forward/reverse or high/low selector, any idea how it will fit in to the current servos. Is it just the brake that I have to attach. How can I put it in neutral (idle) and go forward when only accelerate

The clutch on the engine is what makes it go/engage and be at "neutral" when idle. The knob on the trans was just for high/low gear range. I had an aftershock, it didn't come with the high/low knob or the reverse gears. So all you connect to the trans is the servo to the brake with the other side of the servo going to the throttle:

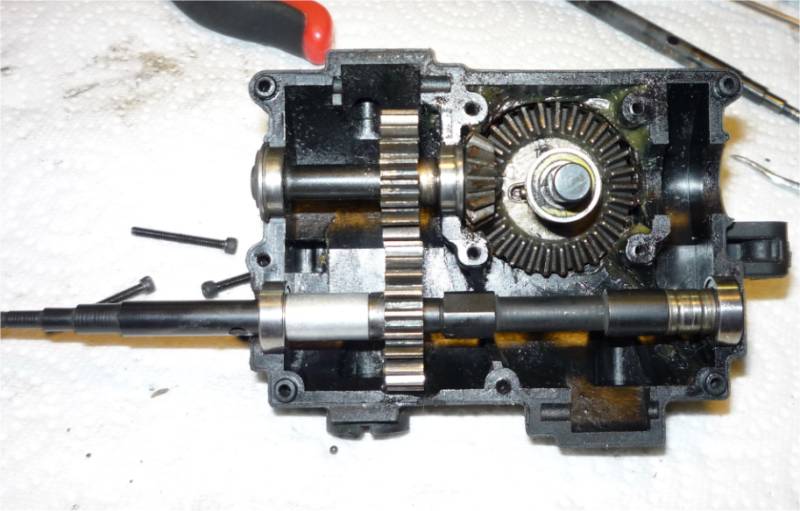

There was a "gear flip" mod that people did back then too. It was similar to adding +1 to the cb tooth count to pick up some speed. Especially if you ran smaller more standard tires. This is what the inside of my aftershock trans case looked like:

The two gears on the left were switched. The one on the bottom in the pic (top of the trans) is larger than the other one. You can see where I had to grind a bit out of the trans case so it would fit. Also had to fiddle with shims I think. Has been a while. That photo was from 2008.

I ran traxxas 3.8" talons on mine. I hated the big ass losi tires. Made the thing handle like a pig. With the smaller lighter tires and the higher output engine (LRP28S3 vs M26SS), I did the gear flip mod AND bought a threaded CB with pinions that were +2 over stock from RC Monster. I ran it that way for most of it's life.

There was a "gear flip" mod that people did back then too. It was similar to adding +1 to the cb tooth count to pick up some speed. Especially if you ran smaller more standard tires. This is what the inside of my aftershock trans case looked like:

The two gears on the left were switched. The one on the bottom in the pic (top of the trans) is larger than the other one. You can see where I had to grind a bit out of the trans case so it would fit. Also had to fiddle with shims I think. Has been a while. That photo was from 2008.

I ran traxxas 3.8" talons on mine. I hated the big ass losi tires. Made the thing handle like a pig. With the smaller lighter tires and the higher output engine (LRP28S3 vs M26SS), I did the gear flip mod AND bought a threaded CB with pinions that were +2 over stock from RC Monster. I ran it that way for most of it's life.

Last edited:

Thanks for the info, I presume that we have to change from 2P mode on the transmitter as forward /reverse doent work any longer. Do you know how clutch engages from transmitter? Do we have to reprogram it?

Shouldn't need to change anything on the remote. If you remove reverse, you will remove the servo as well, so flipping the switch on the remote won't do anything.

Hmm. Yes. So how does from idle to forward work? Is that just based on acceleration, How does the clutch engage? do we have to key in a transmitter key to something. I looked at the manual and cannot figure that out.

That's what your clutch on the engine does. As engine RPM's go up, the springs on the shoes are overwhelmed and the shoes swing out to rub on the bell to transfer the power to the spur/transmission. Then, as your spur spins up, there's a second set of shoes behind the main spur (I think, been a while) that do the same thing to shift from 1st gear to 2nd gear.

The "knob" on the transmission is a physical internal gear switch that changes the transmissions internal ratio. So technically, the transmission as a whole is a "4 speed" system with reverse.

The aftershock (which is what I had), only had the two speed in the spur. The transmission was a single speed gearbox without reverse. The gears on the outside of the gearbox (the spur gears) is where the 2-speed automatic mechanism is.

The "knob" on the transmission is a physical internal gear switch that changes the transmissions internal ratio. So technically, the transmission as a whole is a "4 speed" system with reverse.

The aftershock (which is what I had), only had the two speed in the spur. The transmission was a single speed gearbox without reverse. The gears on the outside of the gearbox (the spur gears) is where the 2-speed automatic mechanism is.