lambdapriest

RCTalk Racer

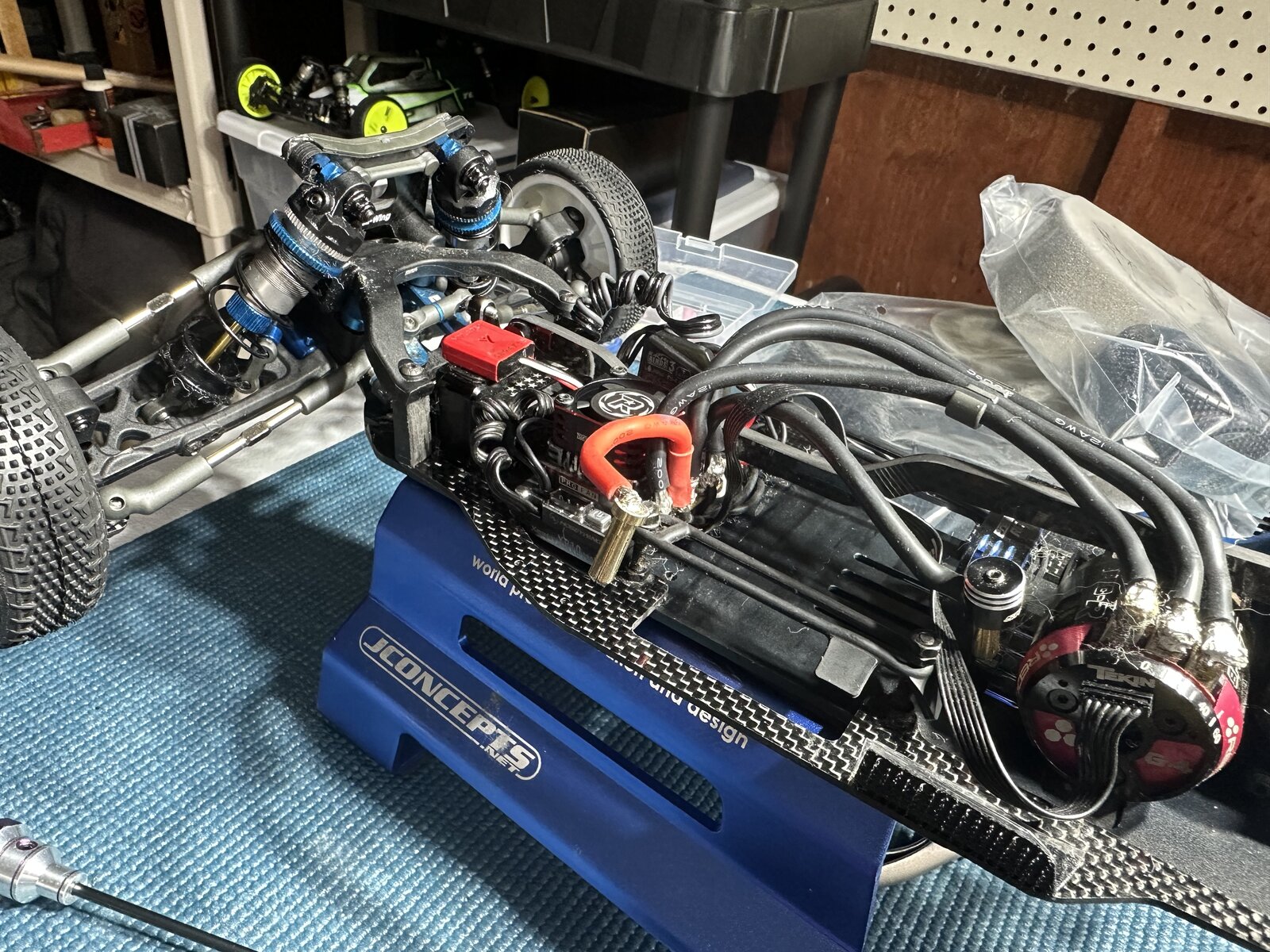

I’m running an Associated B6.4 with the Exotek CB6.4 chassis conversion in the 21.5t stock class, on carpet. I just got a whole bunch of go-fast bits, and I’m (over)due for my first serious round of maintenance on the thing, so I thought this would be as good a time as any to make a thread. I’d like to document my experiences driving the car (as there’s precious little info on the Internet about the Exotek CB6.4), and I think it’ll be nice to look back on this over time and see how the car has progressed. Plus, y’all are a sharp bunch, and I’m looking forward to hearing what the community thinks.

Current setup:

I went to the Exotek chassis because I bent the Associated chassis almost immediately (skill issue); the Exotek looked extremely cool and was only $30 more than the stock chassis, so I went for it!

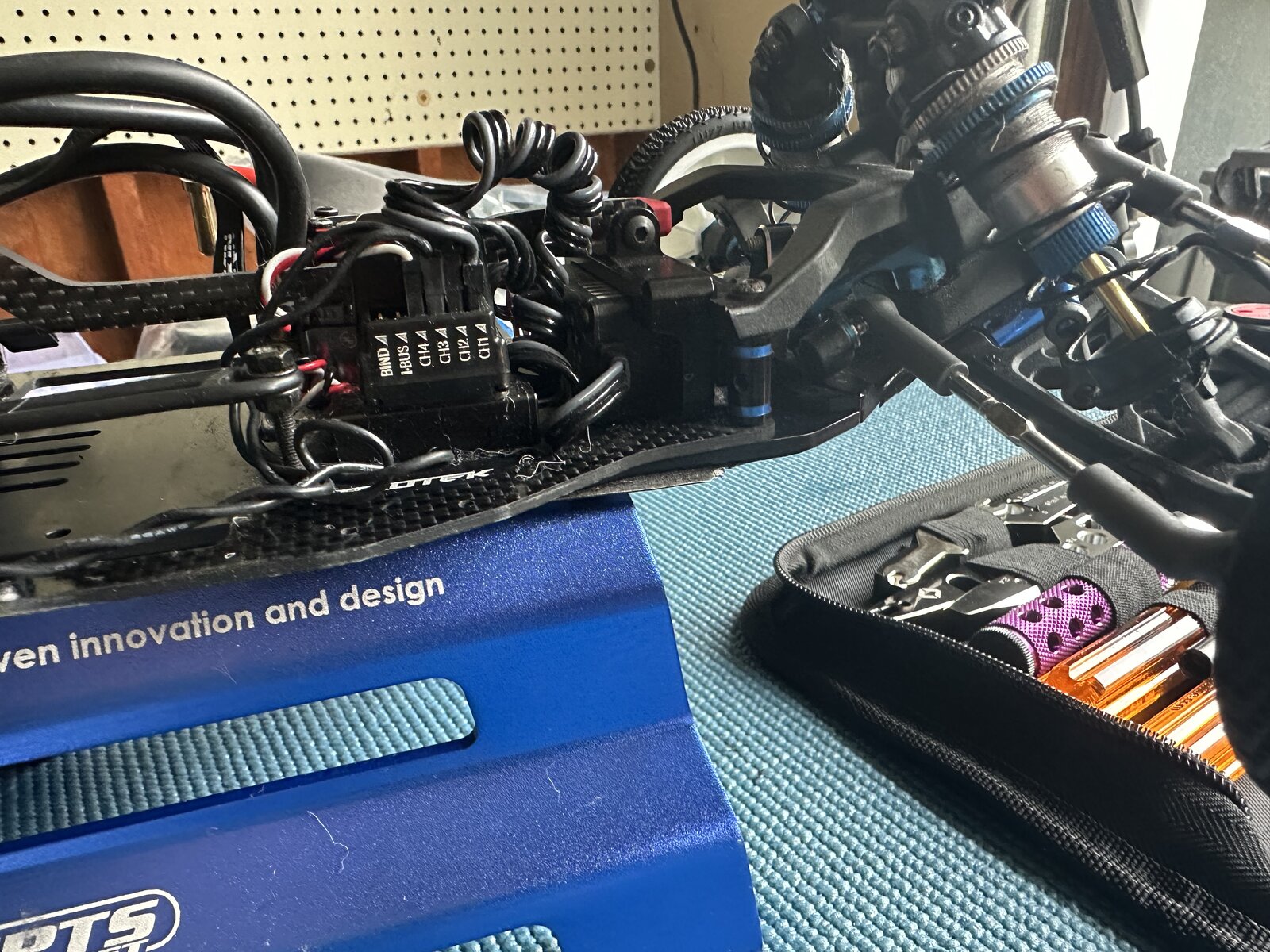

At the moment, the car is in pieces; I’m going to clean the bearings and try to install parts tomorrow, and I’ll take photos. But earlier today, I fixed the most annoying anti-feature of the Exotek chassis, so I figured I’d talk about it for a bit.

Jeez, this post is already pretty long, so I’ll keep it short; the Exotek kit comes with these little threaded barrels that you’re supposed to mount between the chassis and the cowl. You’re supposed to use kit screws. The kit screws that hold in the mud guard are pretty short, and the Exotek chassis is thicker than the stock chassis through that section because of the carbon fiber side rails - so TLDR, the barrels strip right out. I fixed it by cutting and grinding that particular section off of the kit side rails. The replacement barrels from Exotek are $30, because they make you buy the machined aluminum kickup along with them!

Here are some photos of before / during / after:

Current setup:

- Exotek CB6.4 chassis with the LCG shorty cross brace

- Associated orange front springs, yellow rear springs; 35wt Associated oil front, 30wt Associated oil rear (so, kit oil, but with stiffer springs)

- 12mm ride height

- Exotek aluminum wing mount

- Associated aluminum 0deg bulkhead

- Associated aluminum bellcrank arms

- JConcepts Fuzzbite LP front tires and Nessi rear tires, on JConcepts Mono rims

- gensacearespammers 4000mah 130c 2s lipo

- Nitro Pro shorty servo with a Fantom servo horn

- Tekin Gen 4 Spec-R 21.5t motor, 52deg timing @ 4.4 amps

- 31/72 gearing with the Associated slipper eliminator

- Hobbywing XeRun XR10 Pro Stealth ESC

- Protek fan

- JConcepts 6 1/2” turf wing

- Kit everything else

I went to the Exotek chassis because I bent the Associated chassis almost immediately (skill issue); the Exotek looked extremely cool and was only $30 more than the stock chassis, so I went for it!

At the moment, the car is in pieces; I’m going to clean the bearings and try to install parts tomorrow, and I’ll take photos. But earlier today, I fixed the most annoying anti-feature of the Exotek chassis, so I figured I’d talk about it for a bit.

Jeez, this post is already pretty long, so I’ll keep it short; the Exotek kit comes with these little threaded barrels that you’re supposed to mount between the chassis and the cowl. You’re supposed to use kit screws. The kit screws that hold in the mud guard are pretty short, and the Exotek chassis is thicker than the stock chassis through that section because of the carbon fiber side rails - so TLDR, the barrels strip right out. I fixed it by cutting and grinding that particular section off of the kit side rails. The replacement barrels from Exotek are $30, because they make you buy the machined aluminum kickup along with them!

Here are some photos of before / during / after: